Solutions für Device Manufacturing

Device manufacturing is a versatile field that plays a key role in many industries. From precise medical instruments to efficient food processing machines and innovative components for the aviation and automotive industries – device manufacturing drives progress and innovation.

Depending on the field of application, the requirements for electronic components vary greatly. In addition, energy-efficient components and resource-saving manufacturing processes are becoming increasingly important.

Design principles in device engineering

Design principles are like invisible rules of a game that determine how a device is constructed. By following these principles, you can integrate important functions, design modularly for more flexibility, use lightweight construction for efficiency and ensure user-friendliness. With a focus on sustainability and safety, a well-thought-out, high-performance end product is created.

Design

- Functionality: reliable and efficient

- User-friendliness: intuitive and easy to understand

- Aesthetics: appealing and appropriate for the target group

Material

- Strength & durability: resilient and long-lasting

- Weight: light

- Costs: within budget

Ergonomics

- Comfort: pleasant to use

- Safety: minimise potential hazards and meet safety standards

- Accessibility: elements are easy to reach and understand

Safety & standards

- Compliance: adherence to standards and legal regulations (e.g. CE, ISO)

- Safety mechanisms: implementation of protective devices and emergency shutdowns

Modularity

- Interchangeability: replacement of components for maintenance & repair

- Expandability: possibility of expansions & upgrades

Sustainability

- Environmentally friendly materials: recycled or biodegradable

- Energy efficiency: energy-efficient and resource-saving

- Longevity: long lifespan and easy maintenance

Manufacturability

- Manufacturing techniques: optimised design for the selected manufacturing technique

- Assembly: simple and with few parts

Prototyping: The first step towards innovation

Prototyping is a crucial step in the product development process. Prototyping is the development of a preliminary model of a device or product. This helps to:

- test and refine concepts,

- identify design flaws and technical problems at an early stage,

- obtain valuable feedback from users and stakeholders,

- estimate production costs and identify cost reductions.

There are different types and phases of prototyping in device manufacturing. Here’s a concise rundown for you:

- Digital mockups: These are complete, realistic digital models of a product.

- Concept prototypes: These are non-functional models that represent the general appearance and basic idea of a device.

- Functional prototypes: These are models that show the intended functionality of the device, but with temporary or simplistic components.

- Visual prototypes: These are models that show the final design of the device, but are not functional.

- Precision prototypes: These are models that closely resemble the final product in appearance, function and materials.

No minimum order quantity?

Bürklin says Yes!

Selected manufacturer available starting at 1 item. The perfect fit for your prototyping project!

Materials for prototyping: Our services for your project

We know that the first models of a new device require much smaller quantities than in actual production.

To make things easier for you, we offer an extensive portfolio that can be ordered from just 1 item. There is no minimum order quantity, so you can purchase the right number of components for each project.

And the best thing is: we also supply eCAD models for our components, which you can use to easily add the necessary components to your CAD software.

Design your visions: extensive product range for prototyping

Applications in device manufacturing: 3 industries that benefit from customised solutions

There are many areas of application in device manufacturing. In medical technology, precise devices improve patient care. In food technology, hygienic machines ensure safe production. In the automotive industry, innovative, durable components drive development.

Each industry has its own requirements, which are optimally met by customised solutions.

Biocompatible components in medical technology

Medical device manufacturing is particularly demanding due to strict regulatory requirements, such as compliance with the international ISO 13485 standard, and the use of biocompatible materials such as titanium, stainless steel and special synthetic materials.

Whether for medical diagnostic devices, surgical instruments or implants, the selected components must meet all requirements. We support you in your product selection with precise components that have been specially developed for medical technology.

Invisible heroes: our medical technology range

Highest hygiene standards in the food & beverage industry

The F&B industry is also characterised by strict standards such as HACCP. Hygiene is the top priority. Therefore, the components used in food industry equipment must not only be food-safe, but often also corrosion-resistant. In addition, a certain traceability of the components must be ensured.

The hygienic design thus determines which components can be used. They must be rust-free, germ-free and food-safe. We have summarised the most important product features for you in our blog post:

Hygienic Design: Products for the Food & Beverage IndustryDetectable and hygiene-friendly solutions from HellermannTyton

HellermannTyton offers customised solutions for the F&B industry: from detectable cable ties that comply with the HACCP standard, to hygienic PVC tubing and labels that are resistant to corrosion.

In the food industry, only products that meet the highest hygiene and safety standards are used. Detectable cable ties that comply with the HACCP standard minimise the risk of contamination, while easy-to-clean PVC tubing ensures hygiene. Corrosion-resistant identification labels also provide permanent identification in demanding environments. These products make an important contribution to quality assurance and help to maintain the highest standards.

Producers of top-quality food also place the highest demands on the manufacturing process. For this reason, all product solutions presented here comply with the REACH regulation (EC) no. 1907/2006 and are free of DEHP (Bis(2-ethylhexyl)phthalate), a plasticiser classified as toxic to reproduction.

View detectable cable ties

Test device for standardised testing of electrical installations

Gossen Metrawatt's PROFITEST PRIME helps you to test the effectiveness of protective measures in electrical installations in accordance with the standards. The test device enables you to carry out the tests in less time and at lower cost.

The PROFITEST PRIME combines a wide variety of applications in a single instrument and enables all measurements to be made without the hassle of reconnecting the test leads. The test instrument can also be used internationally thanks to the language selection.

View PROFITEST PRIME

Hygiene is top priority: Our product portfolio for the food and beverage industry

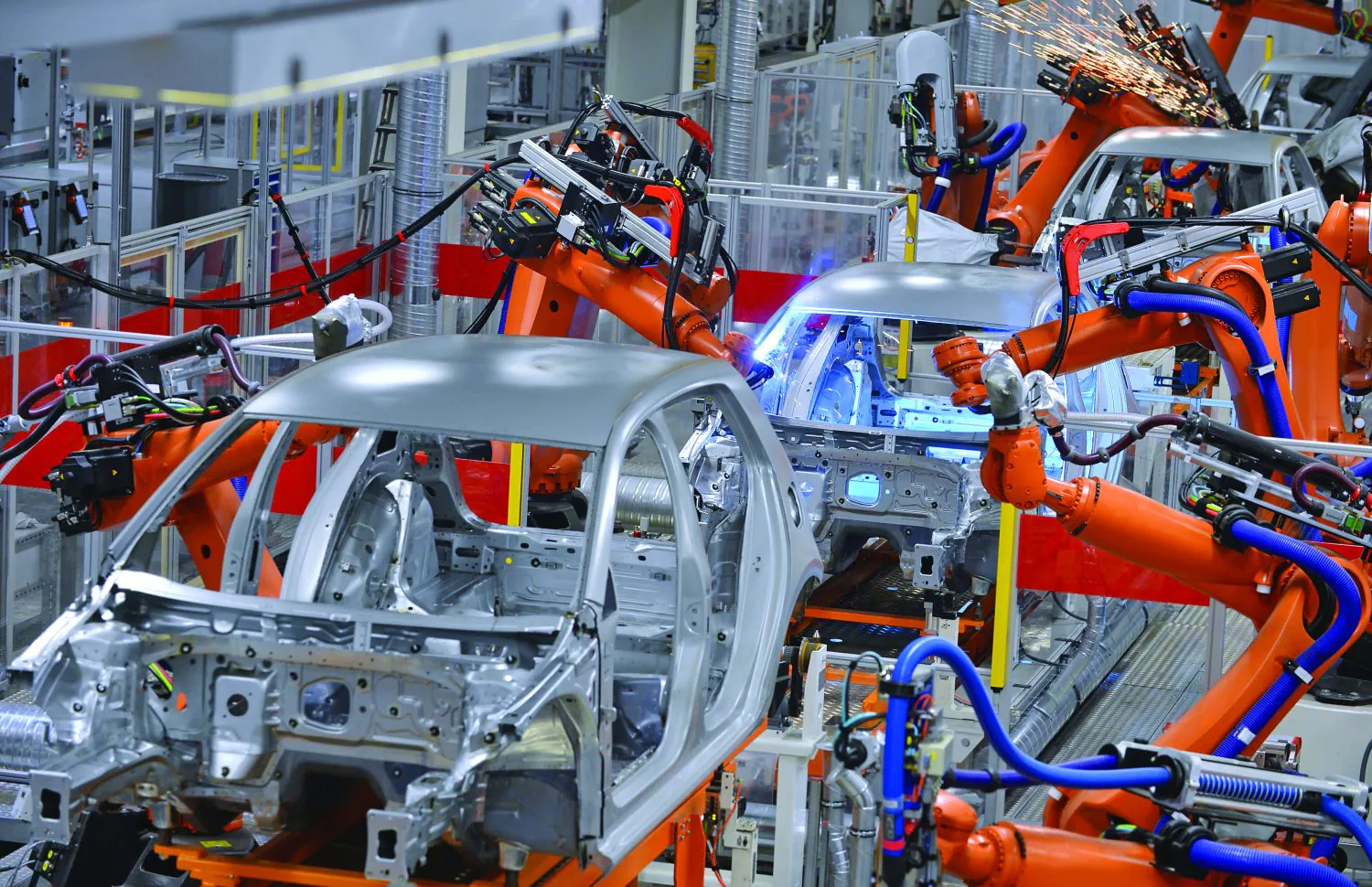

Precision for the automotive industry

We know that the automotive industry depends on precision, durability and cost efficiency. With the electrification of the powertrain, modern technologies are becoming increasingly important and the technology more complex. Individual components must meet increasingly specific requirements, for example, in the area of autonomous driving.

As a result, we have added high-quality, durable and precise components to our product portfolio that meet the strict requirements of the automotive industry.

Flexible and robust cable management solutions for the automotive industry

The soft TEXTIE hook and loop fastener from HellermannTyton is the ideal solution for the automotive sector, especially for applications where sensitive components need to be bundled and protected. It provides a secure hold without leaving pressure marks and is therefore perfect for temporary fastenings, such as during the production of cable harnesses.

The hook and loop fastener makes the TEXTIE quick and easy to apply by hand, and it can be reused up to 400 times. It can be used both indoors and outdoors. The choice of colours – black, green, red and white – also allows for flexible labelling.

View fasteners

The reusable polyester Twist-In braided sleeving is the ideal solution for the automotive industry, especially for pre-assembled wires or for retrofitting. Thanks to its easy handling, the sleeving can be opened with a single hand movement, making it easier to maintain, repair and inspect the cable bundles.

Twist-In enables effortless bundling and quick cable removal without the need to remove connecting elements or accessories. With its excellent abrasion protection, it is frequently used in the automotive industry, in mechanical engineering and in electrical installations – and also offers reliable cable protection in home offices and entertainment systems.

View reusable braided sleeving

High-quality automotive components at Bürklin

Innovations and trends: a glance at the future

Where is the road leading in the field of device manufacturing and its specific areas of application? New technologies and ideas are creating smarter, more efficient and more sustainable devices. Trends such as digital networking and environmentally friendly materials are driving the industry forward and setting new standards. We have summarised the five most important trends for you:

Materials and technologies

- Lightweight yet strong materials: Advances in material science are leading to the development of new materials, such as carbon fibre composites, graphene and high-performance polymers, that are both lightweight and extremely strong.

- Nanotechnology: Nanomaterials and techniques improve the properties of devices, such as strength, conductivity and durability.

- Printed electronics: Electronic components and devices made or enhanced by printing techniques enable more flexible and cost-effective devices.

Sustainability in focus

- Sustainable materials: The use of recycled and bio-based materials helps to reduce the environmental footprint of device manufacturing.

- Energy efficiency: Innovations in the energy efficiency of production facilities and end devices help to reduce energy consumption and operating costs. They also have a positive impact on the environment.

- Circular economy: Reuse and recycling are becoming increasingly important. Modular design can minimise waste and conserve resources.

Artificial intelligence and machine learning

- Predictive maintenance: AI algorithms analyse equipment data to predict potential failures and enable preventive maintenance.

- Optimisation of manufacturing processes: machine learning can be used to optimise production processes and increase efficiency by recognising patterns and making adjustments in real time.

Automation & robotics

- Automated manufacturing processes: Automation in manufacturing is constantly advancing. Robots and automated systems are taking over more and more tasks in device manufacturing – from assembly to quality control. This increases efficiency and reduces errors.

- Cobots or collaborative robots: The trend is moving more towards cobots, robots that work directly with humans. They offer a flexible solution for repetitive or dangerous tasks.

- Internet of Things (IoT): The integration of IoT technologies enables the networking of devices and central systems. This improves the maintenance, monitoring and control of the devices. In medical technology, devices such as insulin pumps that are equipped with IoT technology enable continuous monitoring and adjustment in real time. This can significantly improve patient care.

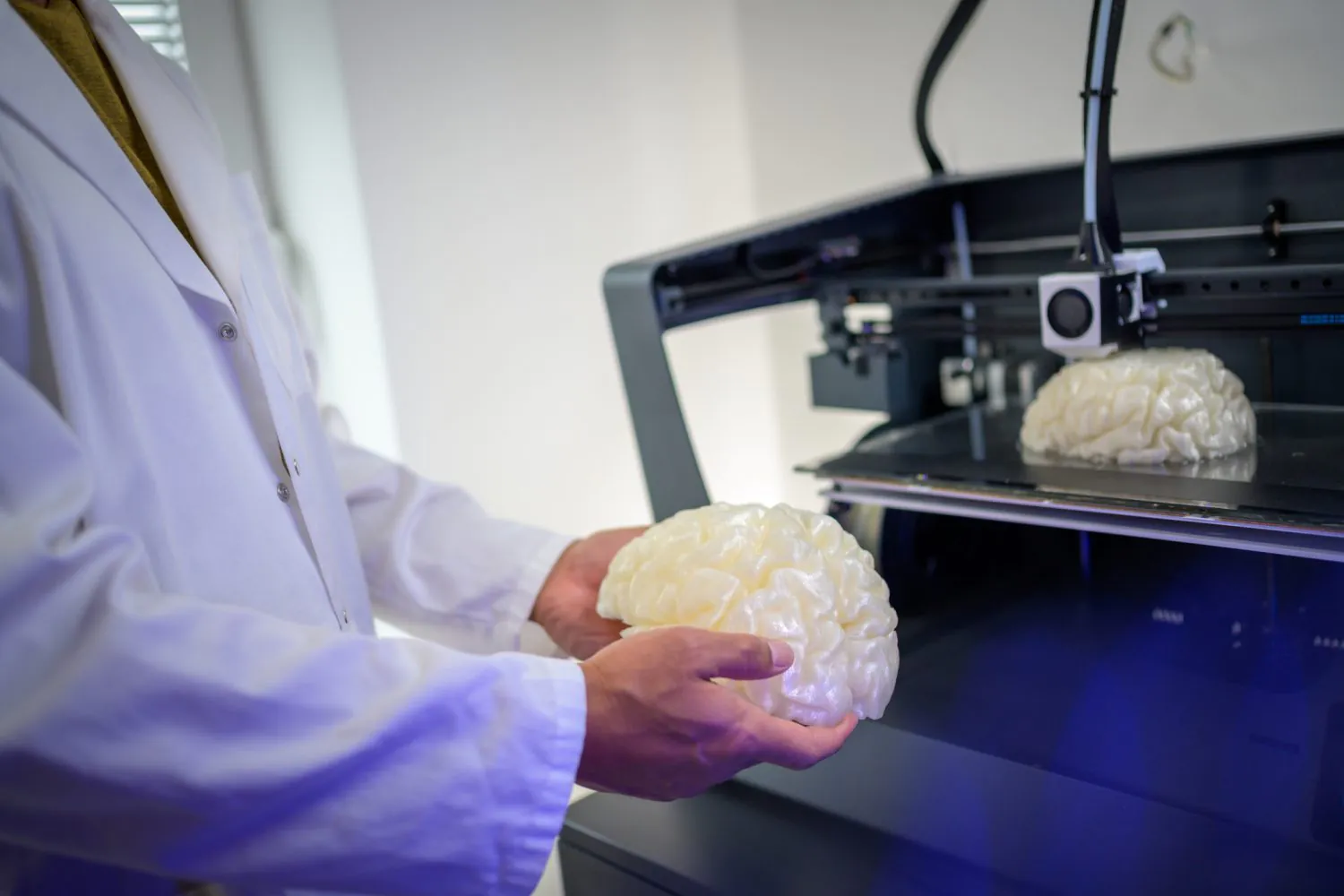

3D printing and additive manufacturing

- Rapid prototyping: 3D printing makes prototyping fast and economical, thus shortening product development cycles.

- Customised solutions: additive manufacturing allows the production of customised devices and components in small series, which is particularly advantageous in niche markets.

Sustainable cable management reinvented: environmentally friendly cable ties, ergonomic cable tie application tools and conduit for future-proof installations

HellermannTyton offers innovative and sustainable solutions for device manufacturing. The EVO series processing tools and cable ties made of polypropylene (PP) are highly efficient and environmentally friendly. Polypropylene has a lower carbon footprint and is highly recyclable.

The EVO tools enable precise and ergonomic processing of cable ties, making installations more efficient and convenient. The PP cable ties S50ROS and our corrugated conduit holders are not only particularly robust, but also durable and versatile – ideal for use in demanding environments in equipment manufacturing. This combination of innovation and sustainability helps to reduce the ecological footprint.

View sustainable solutionsPCB terminal blocks, connectors and electronic housings made of bio-based plastics

Phoenix Contact is committed to a gradual transformation of its products towards greater sustainability. An increasing number of solutions are already finding their way into the Phoenix Contact product range that, thanks to process optimisation and the use of more sustainable materials, have significantly improved CO2 footprints compared to their conventionally manufactured product series.

Initial solutions with optimised sustainability are already available in the product categories of PCB terminal blocks, connectors and electronic housings. This has been achieved, for example, by using bio-based plastics developed on the basis of the castor oil plant.

Castor oil plants for a smaller carbon footprint

The oil of the castor oil plant is the basis for CO2-reducing plastics. This crop has a number of ecological advantages, as it does not compete with the cultivation of food or animal feed. Castor oil plants grow in dry areas that are not suitable for other types of agriculture and therefore do not require additional land. They do not need fertiliser or irrigation. Based on this sustainable resource, significant CO2 savings can be achieved in plastic-based components.

Discover sustainable PCB connectors

Janitza: Expert in energy measurement technology

Janitza manufactures energy measurement technology to improve energy efficiency and ensure security of supply.

The portfolio includes innovative measurement devices and the perfectly matched network visualisation software GridVis® - supplemented by high-quality components and combining energy data management, power quality monitoring and residual current monitoring in a single system environment.

Janitza makes energy flows transparent - for the responsible use of energy resources and for more sustainability.

View Power Analysers

Reliable power supplies from WAGO: from simple installations to complex automation solutions

WAGO offers high-performance and efficient power supplies that ensure a stable power supply for a wide range of applications – from simple installations to complex automation solutions with high power requirements. The product range includes solutions such as the WAGO Pro 2, which impresses with high efficiency, connectivity and flexible configuration. With an efficiency of up to 96.3%, it saves resources and is future-proof.

For smaller applications, the WAGO Eco and Eco 2 Series offers an excellent price-performance ratio in compact housings, supplemented by a fast, tool-free connection. The space-saving WAGO Compact Series is also ideal for installation and system distribution.

In addition to the reliable power supply, WAGO's uninterruptible power supplies (UPS) ensure that your applications continue to run smoothly even during voltage dips or power outages. In addition, we offer DC/DC converters for special voltages and redundancy modules to protect against power outages. WAGO power supplies provide you with solutions that are not only efficient and space-saving, but also offer maximum flexibility and security for your systems.

WAGO power supply units for every applicationBürklin delivers: Your partner for customised solutions in appliance construction

We know that device manufacturing requires more than just the proper, high-quality components. That is why we have tailored our supplier management specifically to the needs of device manufacturing.

We understand that the selection and coordination of reliable suppliers is crucial for the quality and efficiency of your production. That is why we offer:

- a wide selection of high-quality components,

- high delivery reliability and short delivery times,

- customised solutions such as blanket orders or scheduled deliveries,

- state-of-the-art products to meet the most modern requirements.

Become part of our community!

Would you like to stay up to date on innovations and product developments in the field of device manufacturing and others? Then sign up for our newsletter and receive all important information.

Customer-focused service

70 years of expertise

Customised procurement solutions

Regional location

Resources for device engineering

Sustainable Manufacturing: Sustainability Approaches for the Manufacturing Industry

How can the manufacturing industry become more sustainable and what are the benefits? We highlight various sustainability approaches - from raw material management to circular economy to CSR reporting.

Read now!

Hygienic Design: Products for the Food & Beverage Industry

What does Hygienic Design mean? Which cables and wires are suitable for use in the food and beverage (F&B) industry? In which areas does the food industry rely on automation technology? It is time to get to the bottom of these and other questions.

Read now

Traceability in the Industry

Consumers are regularly informed about recalls of defective products. For affected companies this is usually associated with high financial expenditure and image damage. But how does it come about? How can quality defects be detected early on? And to what extent can product traceability provide a remedy?

Read now!

Safety in Equipment and Mechanical Engineering

In the complex segment of equipment and mechanical engineering, the safety factor plays a central role alongside quality and usability. Depending on the type of equipment and area of application, specific legal requirements apply to the production and use of electronic components. We offer you an overview of legal requirements, mandatory standards and the significance of various safety-relevant components. We accompany you on the way to more reliability and risk prevention in the modern construction of electronic systems.

Read now!

Usability Engineering in Equipment and Mechanical Engineering

Equipment and mechanical engineering are often complex and confusing. But it is precisely here that usability engineering can help to simplify the operation of machines and thus increase productivity. Find out exactly how this works and what advantages it offers in our article. Learn how you can increase the efficiency of your production through usability engineering and thus save time and costs.

Read now!

Quality in Equipment and Mechanical Engineering

In times when energy- and cost-efficient solutions are sought in virtually every area, the desire for long-lasting and robust products and components is increasingly noticeable in equipment and mechanical engineering. But what is connected with the demand for quality? How do high-quality products influence the production process?

Read now!

Connectivity Solutions in Medical Technology

Whether in the operating room, in doctors’ offices or for Mobile applications: In the field of medical technology, the quality of technical components can be relevant to health and sometimes even critical to life. In this highly sensitive area, enormously high demands are therefore placed on technical components - including connectors and connectivity solutions. What do connectors, cables and connectivity solutions have to do in medical technology and how do manufacturers react quickly to the needs of the industry?

Read now

Titanium: Important Material in Medical Technology

Titanium is one of the most powerful and reliable materials in medical technology. What are titanium's characteristics that make it so special? And what is important when processing this material? Learn more about the characteristics and possible applications of titanium in medical technology.

Read now!

How 3D Printing enriches Medicine

Industry has long since discovered the advantages of 3-D printers for itself. But there is no question that this innovative manufacturing technology is also revolutionizing medicine, given current developments. What possibilities does the 3-D printer already offer for medicine today? And what developments can be expected in the future?

Read now!Frequently asked questions about device manufacturing

What is device & equipment manufacturing?

Appliance manufacturing refers to the process of designing and manufacturing appliances for various industries, including medical, food processing, automotive and many others. This can range from the design of individual components to complex machines and systems.

What are the most important requirements in device manufacturing?

The most important requirements in device and equipment manufacturing are high reliability, durability, energy efficiency and compliance with industry standards and regulations. In addition, the ability to develop customized solutions that meet specific needs and requirements is crucial.

What challenges need to be overcome when using electronic components in device manufacturing?

Challenges when using electronic components in device manufacturing include selecting the right components, ensuring they are compatible with each other, complying with standards and regulations and overcoming problems such as heat dissipation and EMC (electromagnetic compatibility).

How can energy efficiency and resource conservation be implemented in device manufacturing?

Energy efficiency and resource conservation in device manufacturing can be achieved by selecting energy-efficient components, optimizing the design and operating conditions of devices, using renewable energy and reusing or recycling materials and components.

What standards and guidelines are there for device and equipment manufacturing?

The most important standards and guidelines in device and equipment manufacturing are:

- DIN EN ISO 9001: Quality management systems

- DIN EN ISO 9001: Quality management systems

- DIN EN 60204-1: Safety of machinery - Electrical equipment of machines

- DIN EN 13849-1: Safety requirements for machinery - Principles for design

What are the trends in device and equipment manufacturing?

Current trends in device and equipment manufacturing include increasing digitalization and automation, the use of artificial intelligence and machine learning, the development of smart devices and IoT (Internet of Things), the increasing importance of sustainability and energy efficiency and the development of new materials and technologies.