MRO: Maintenance, Repair & Operations

Maintenance, Repair and Operations (MRO) is a crucial aspect of any business. In order to be successful and maintain smooth operations, machines and systems must be regularly serviced, repaired and maintained.

MRO solutions for efficient operating processes

A well-organised MRO strategy enables optimal use of existing resources, minimises downtime and extends the service life of assets. An efficient MRO strategy plays a decisive role in the smooth running of operating processes. It helps to optimise systems, minimise downtime, improve safety and reduce costs in the long term.

All about maintenance strategies

MRO optimisation with predictive maintenance: increase the efficiency of your systems

Predictive maintenance is a maintenance method based on the Industrial Internet of Things (IIoT). By utilising machine data, signs of wear and maintenance requirements can be precisely determined. In contrast to conventional regular maintenance, predictive maintenance enables demand-based maintenance, which leads to minimised downtimes, higher productivity and more efficient maintenance. Personnel and material resources are also minimised.

However, a number of challenges have to be addressed for predictive maintenance to be successful, in particular the correct handling of data. Sensors play an important role in monitoring the condition of machines and recognising signs of wear at an early stage.

In the world of MRO, predictive maintenance is a decisive factor in increasing efficiency and reducing costs. By detecting potential problems at an early stage, predictive maintenance enables planned, preventive maintenance to minimise downtime and extend the service life of equipment.

All about predictive maintenanceOur wide range of predictive maintenance solutions offers companies the tools and technologies they need to successfully implement the step towards proactive maintenance. From sensors and monitoring systems to predictive models, we offer customised solutions that are individually tailored to the requirements of each company.

We support you in making optimum use of your systems, minimising downtimes and ultimately strengthening your competitiveness on the market.

Our range for predictive maintenance solutions

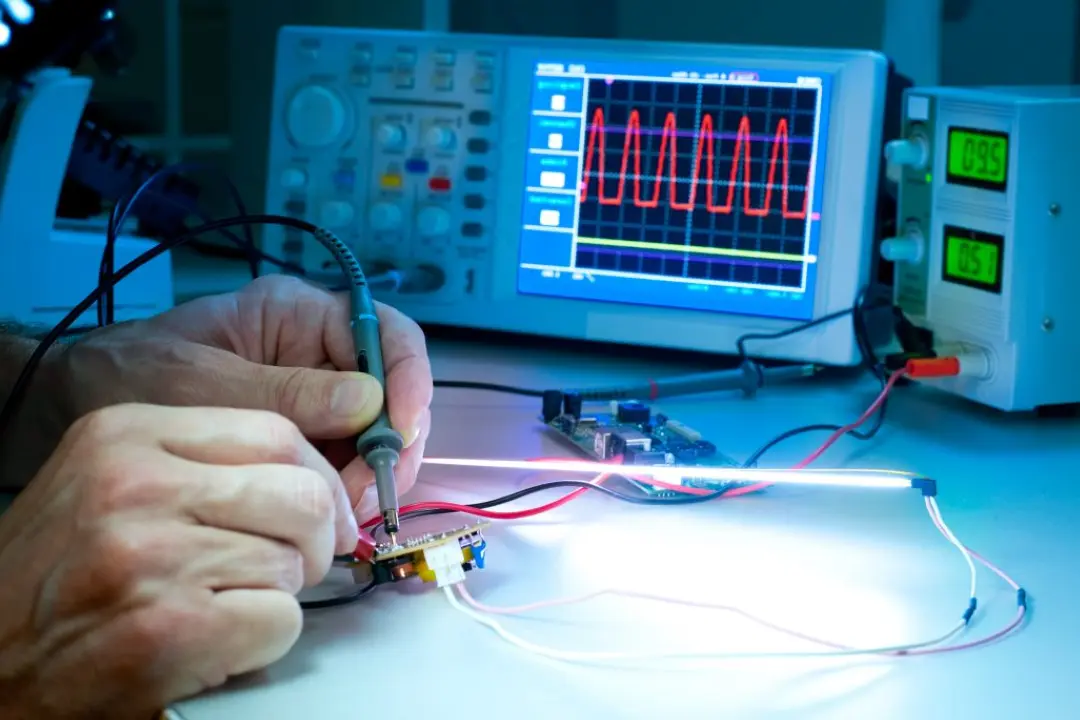

Precise measurements for efficient maintenance - the importance of MRO in measurement technology

Maintenance and repair (MRO) is all about minimising downtime and staying in control. Precise measurements play a crucial role in maintaining systems efficiently and tackling problems proactively.

Any error can have expensive consequences, so the right tool for error diagnosis is essential. This is where measurement technology comes into play to check performance values, localise defects and monitor components.

With our range of high-quality measuring devices, we enable precise measurements to quickly recognise and rectify problems. Be it error diagnosis, regular maintenance or the avoidance of expensive breakdowns - with precise measurements, we offer our customers solutions for efficient system maintenance.

Our product selection for precise measurements

MRO tools: Efficient solutions for facility maintenance

The ability to solve problems quickly and efficiently - whether it's maintaining machines, repairing components or overhauling systems - is extremely important. Every move has to be right in order to solve problems effectively and get systems up and running again quickly.

We prioritise quality and reliability, and our range of tools and equipment is designed to help our customers overcome any challenge.

Quality is the key to success. Our wide range of products includes everything from hand tools and power tools to specialised tools for specific applications. With us, you can be sure that you have the right tools for every job. They are the key to efficient plant maintenance.

Our selection of high-quality MRO tools and tools

Safety comes first: personal protection equipment

Solutions from our manufacturers for successful maintenance

Discover solutions from well-known manufacturers that will equip you with the tools to implement a successful MRO strategy.

Sensors from Würth Elektronik for demand-orientated maintenance

To introduce a successful predictive maintenance strategy, you not only need big data, but also right data. It is therefore crucial to know and collect the relevant data for the respective solution. Würth Elektronik offers various solutions for this, e.g. sensors that permanently monitor the condition of machines and systems. Different sensors can be used depending on the type of wear to be expected.

Sensors for detecting imbalance or vibration

Imbalances or vibrations are often caused by bearing or gearbox damage, defective shafts, loosening of anchorages, belt wear or damage to the blades of windmills and turbine wheels. 3-axis acceleration sensors such as the WDEN-ITDS from Würth Elektronik are suitable for detecting such damage.

This measures the acceleration for each of the three spatial axes separately so that the installation position does not have to be taken into account. Any rotations can be compensated for by matrix calculations.

Wear on mechanical components often manifests itself in the fact that machine parts change their vibration behaviour. This can also be recognised with an acceleration sensor. The output signal of the sensor is spectrally analysed, usually using Fourier transformation. The aforementioned damage leads to a change in this spectrum, usually due to the occurrence of various harmonics. The absolute value then no longer serves as a benchmark, but the relative change in the spectrum as an indication of incipient wear.

Acceleration sensors from Würth Elektronik

Sensors for detecting filter states

Pressure sensors are a suitable solution for determining the ideal time to replace or clean filters. When particles clog the filter, the back pressure rises, which leads to an increasing pressure difference before and after the filter. The WSEN-PDUS series of differential pressure sensors can be used for this purpose.

Alternatively, depending on the application, it may also make sense to place an absolute pressure sensor, e.g. the WSEN-PADS sensor. The measured values can then be converted into a differential pressure using a microcontroller.

Absolute pressure sensors from Würth Elektronik Pressure sensors from Würth Elektronik

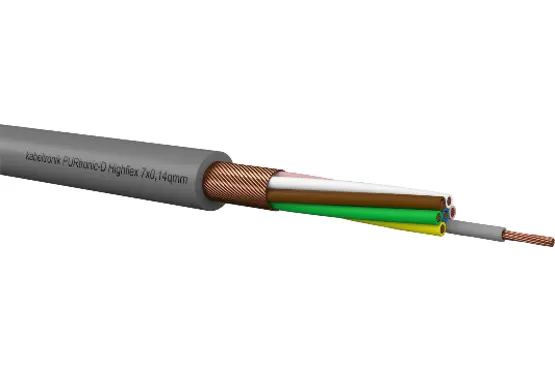

Solutions from LAPP for optimum electromagnetic compatibility in the smart factory

As a leading technology partner, LAPP offers customised solutions to optimise electromagnetic compatibility (EMC) for the smart factory. With the increasing use of high-power electricity and data transmission in confined spaces, the risk of electromagnetic interference is increasing. LAPP supports you with a comprehensive understanding of the system and the right components to ensure optimum EMC.

The various coupling mechanisms such as galvanic, capacitive, inductive and radiation coupling can cause electromagnetic interference. To eliminate this, shielded cables are recommended. The EMC Directive defines electromagnetic compatibility as the ability of a device to operate in its environment without interference.

LAPP offers shielded connection and control cables as well as special EMC connectors with 360-degree shielding. Proper earthing is crucial for good EMC. LAPP's health check service checks the cabling in factories for possible EMC problems.

For unshielded wires, there are options for subsequent EMC shielding such as copper braiding or shielding tapes. LAPP offers pre-assembled wires with EMC shielding to avoid assembly errors and ensure high quality. LAPP's zeroCM® technology sustainably improves EMC in machines and systems.

Connection and control cables from LAPP

How to choose the right cable with kabeltronik®

In industrial applications, choosing the right cable is crucial to increase the service life of the installation. Cables are exposed to various extreme conditions that can affect their function and performance. Low and high temperatures, humidity, chemicals and mechanical stresses can cause cables to become damaged and fail prematurely.

To avoid this, it is important to choose cables that meet the specific requirements of the application. Cables should be installed and routed carefully to avoid damage. Regular inspections and maintenance help to recognise and rectify problems at an early stage.

Another important factor for the longevity of cables is the use of high-quality products. At Bürklin, you will find a wide range of kabeltronik® products that are suitable for various applications and are made from high-quality materials.

By selecting and maintaining the right cables, you can ensure that the installation works smoothly for a long time and avoid breakdowns. Therefore, invest in high-quality cables and carry out regular maintenance to extend the service life of your installations.

Connection and control cables from kabeltronikBürklin delivers: Our services for efficient MRO processes

Click on a service to find out more about it.

Become part of our community!

Do you want to stay informed about the latest developments in MRO and other topics? Become part of our community and sign up for our newsletter. This way you will not miss any news about products and innovations.

Customer-focused service

70 years of expertise

Customised procurement solutions

Regional location

Guides and things to know for successful maintenance

Inspection Techniques in Electrical Engineering

Inspection techniques in electrical engineering are indispensable for ensuring the safety and functionality of electrical systems. But what methods are there and how can they be used effectively? In our article, we give you an overview of the most important inspection techniques and show you how to detect and eliminate faults at an early stage.

Read now

Facility Inspection with Thermal Imaging Cameras

Thermal imaging cameras are an efficient tool for facility inspection and make a significant contribution to increasing occupational safety. But what exactly are the areas of application for thermal imaging cameras and what advantages do they offer? In our article, we will also give you an insight into facility inspection with thermal imaging cameras from Fluke and show you how this technology can save you time and money.

Read now

DIN 31051: Fundamentals of Maintenance

Keeping technical facilities in good shape when it comes to their efficiency, operational safety and longevity requires careful maintenance. The standard DIN 31051 offers a structured approach to effective maintenance and improvement of objects through four clearly defined measures. We break down the profitable topic in detail for you.

Read now

Maintenance 4.0: Predictive Maintenance

Industrial maintenance in the fourth wave on the test bench: Technical failures and reduced production quality due to wear and tear of machines and materials lead to massively increasing costs in industry. The change from reactive to preventive measures is inevitable. In the article, you can read about potentials, challenges and practical examples.

Read nowKnow How Hub Maintenance

In our online magazine "Electronic Competence", we look at how companies can optimize their maintenance processes and minimize downtimes and maintenance costs. What are the advantages of condition monitoring via the digital twin, how efficient is predictive maintenance, and why do big data analytics play such a key role in this?

Explore our Know How Hub

Frequently asked questions about MRO

What does the abbreviation MRO stand for?

MRO stands for Maintenance, Repair and Operations. It is a collective term for activities and processes related to the maintenance of assembly, machines, buildings and infrastructure in an appropriate condition.

What are the key elements of an effective MRO strategy?

An effective MRO strategy requires complete control over stock levels, a precise knowledge of the company's needs and requirements and close cooperation between the various departments involved in indirect procurement.

What are the benefits of a well-organized MRO strategy?

A well-organized MRO strategy not only enables optimal use of existing resources and minimizes downtime, but also helps to extend the life of your assets. It can also help to reduce overall costs and increase productivity.

What are MRO products for a successful strategy?

MRO products that are necessary for the daily operation of a company, include tools, spare parts, safety equipment and consumables:

- Wear parts and spare parts for the repair of machines and systems

- Tools for the maintenance and repair of machines and systems

- Lubricants for the maintenance of machines and systems

- Operating materials such as cleaning agents and auxiliary materials

- Protective equipment for employees in the MRO department

These products are not directly incorporated into an end product, but are essential for the proper operation and maintenance of machines and systems.

How do you choose the right MRO products?

Choosing the right MRO products requires a thorough understanding of the company's needs and requirements. It is important to make a list of the MRO products that are essential to your business operations. In addition, a supplier's service should be the deciding factor, not just the price.