Capacitors in Focus: Aluminium Electrolytic Capacitors from Würth Elektronik Uncovered

Capacitors form two-thirds of all electronic components. There are a variety of technologies that make the selection quickly complex. In particular, aluminium electrolytic capacitors have a firm place in numerous applications due to their high capacity and versatility. Together with Würth Elektronik, a pioneer in capacitor technology, we take a close look at this product group: How are they constructed? Which capacitor types are suitable for which applications? What factors determine the lifespan?

What are capacitors?

Capacitors accumulate energy in the form of an electrical field. They essentially consist of two conductive plates (electrodes) that are separated from each other by a non-conductive material (dielectric). When an electrical voltage is applied between the two plates, electrical energy is accumulated.

Capacitors are used for a wide range of applications, such as voltage stability, in filter circuits, in energy storage or as coupling and decoupling components in circuits. Due to the wide range of applications, there are many different types, including ceramic capacitors, tantalum electrolytic capacitors, film capacitors and aluminium electrolytic capacitors.

What are aluminium electrolytic capacitors?

Aluminium electrolytic capacitors are a special type of capacitor that offers high capacitance per unit volume. They consist of two aluminium foils and a paper soaked in electrolyte. The anodic aluminium foil has an oxide layer that acts as a dielectric. The liquid or solid electrolyte substance serves as a cathode.

The capacitors are frequently used in power supplies, audio amplifiers and DC link circuits. Among other things, they serve as smoothing capacitors, energy stores or for decoupling signals.

Aluminium capacitors from Würth Elektronik

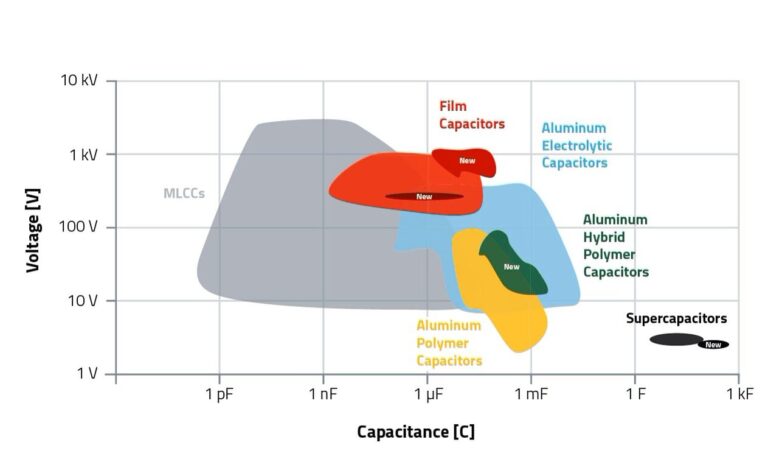

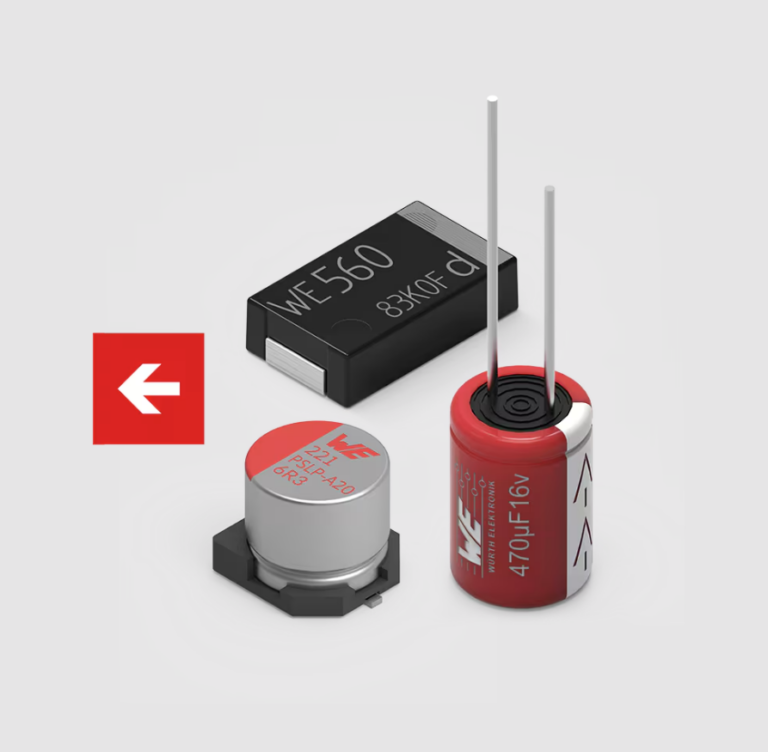

Würth Elektronik is a pioneer in capacitor technology and offers a wide range of capacitors for various applications. The portfolio includes film capacitors, MLCCs, aluminium-polymer capacitors, aluminium hybrid polymer capacitors and aluminium electrolytic capacitors. The aluminium hybrid polymer capacitor product family is the latest addition to the product portfolio and combines the technologies of aluminium electrolytic and aluminium polymer capacitors.

Aluminium electrolytic capacitors from Würth Elektronik

Würth Elektronik aluminium electrolytic capacitors offer stable capacitance values at high temperatures compared to film capacitors and MLCCs. In addition, the electrolytic capacitors offer higher voltage values compared to aluminium polymer capacitors and a lower leakage current. The stable capacitance values are based on the DC bias voltage. These capacitors are used in digital cameras, forklifts, computers, control panels and elevators.

Aluminium-polymer capacitors from Würth Elektronik

Würth Elektronik’s aluminium polymer capacitors have low ESR (Equivalent Series Resistance) over a high frequency range and a high permissible AC current. Compared to aluminium electrolytic capacitors, they have a longer lifespan. They also have stable capacitance values with respect to DC bias and ambient temperature. They are therefore suitable for applications in routers, graphics cards, industrial computers and in high-performance USB chargers.

Aluminium hybrid polymer capacitors from Würth Elektronik

Würth Elektronik aluminium hybrid polymer capacitors combine the technologies of aluminium electrolytic capacitors and aluminium polymer capacitors. They impress with a long lifespan and a low ESR value. The ripple current characteristic is high. With a low leakage current and high stability over the temperature range, the capacitors are particularly suitable for applications such as servo inverters, air conditioning systems, industrial power supplies or security cameras.

How are aluminium capacitors constructed?

Aluminium capacitors are polar or non-symmetrical in design. This means that the electrodes are divided into an anode and a cathode.

In an electrolytic capacitor, the anode consists of a processed metal foil. The cathode is formed by the conductive electrolyte. An oxide layer on the metal foil of the anode acts as a dielectric. In addition, the oxide layer insulates the electrodes from each other. The main differences between electrolytic capacitors are determined by the electrode material, e.g. tantalum or niobium, and the properties of the electrolyte, solid or liquid.

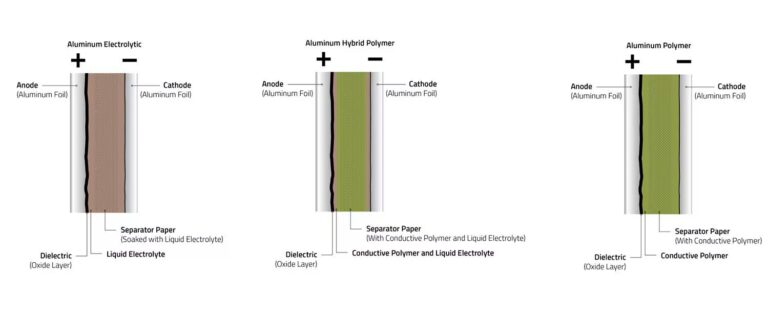

Aluminium electrolytic capacitors are wound capacitors and consist of aluminium foils with a paper layer in between. Before winding, the aluminium foil of the anode is pre-treated by anodic oxidation. This strengthens the oxide layer as a dielectric. The entire winding is then completely soaked in electrolyte. The electrolyte is distributed evenly by the paper layer. In addition, the paper layer acts as a separator and ensures an even distance between the anode and cathode foils.

In aluminium-polymer capacitors, on the other hand, the paper layer consists of a conductive polymer. In aluminium hybrid polymer capacitors, the paper layer consists of a conductive polymer and a liquid electrolyte. This means that the new capacitor type from Würth Elektronik combines both properties in a single product.

The lifespan of aluminium electrolytic and aluminium polymer capacitors

The lifespan of electrolytic capacitors is determined by a number of factors, including temperature, the oxide layer and the placement of the component. This means that the overall lifespan of the application can also be influenced.

Temperatures around and in the component

The temperature around and in the component largely determines the capacitor’s lifespan. Over time, the internal structures age due to the thermal load and the electrical properties deteriorate. This can result in an increased leakage current and a higher ESR. This in turn causes a further increase in temperature.

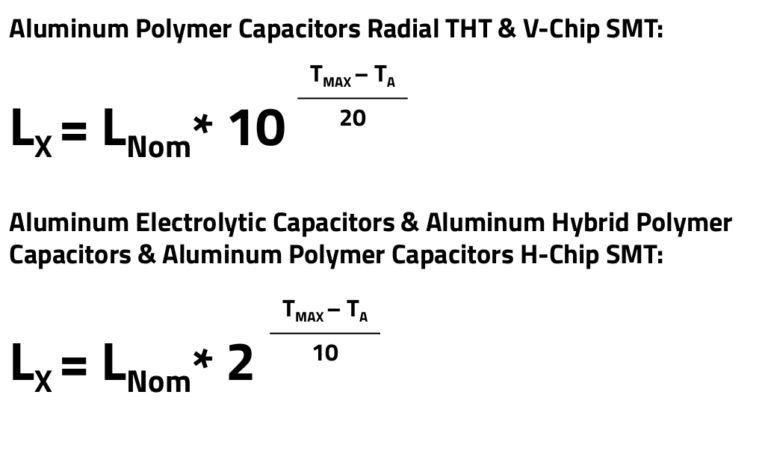

If the limit values are not exhausted, a high life expectancy can be achieved by reducing the temperature load inside the component. For example, the lifespan of conventional aluminium electrolytic capacitors is doubled if the temperature inside the component is reduced by 10°C. For aluminium polymer capacitors, the lifespan can even increase tenfold if the temperature inside the component is reduced by 20°C.

The density of the oxide layer

Another factor for a long service life is the thickness of the oxide layer. The thicker the oxide layer, the greater the potential service life. This oxide layer can be adjusted to a defined thickness during the production process of electrolytic capacitors by applying an electrochemical process called formation. In this process, a voltage is applied to the aluminium foil for a predetermined time. Depending on the voltage and duration, the oxide layer grows to the desired value. The thicker the oxide layer in the component, the higher the voltage that can be applied to this layer later on.

During voltage-free storage, the thickness then decreases again slowly but continuously. This increases the leakage current of the capacitor. In addition, the dielectric strength of the capacitor decreases.

As soon as voltage is applied, the oxide layer reforms and the leakage current decreases. However, the increased leakage current when the capacitor is switched on must be tolerable for the application so that the device can be switched on without malfunction. The loss of capacitance and the increase in ESR can also be compensated for by a well-thought-out dimensioning of the component.

Calculation of the expected lifespan

The expected lifespan can be calculated on the basis of the specified endurance, maximum temperature and the temperature of the application.

The formulas are composed as follows:

- Lx = Expected lifespan of the component

- LNom = Lifespan of the component (see data sheet)

- Tmax = Maximum permissible temperature of the component

- TA = Ambient temperature of the component within the application

Since these formulas initially do not appear to be entirely trivial, the following simplified statements can also be made:

- Aluminium-polymer capacitors SMD + THT: For every additional 20°C below TMax, the expected service life increases tenfold.

- Aluminium electrolytic capacitors & aluminium hybrid polymer capacitors & aluminium polymer capacitors H-Chip: For every additional 10°C below TMax, the expected service life doubles.

Key technology: Aluminium hybrid polymer capacitors

Aluminium electrolytic capacitors are suitable for many different applications – from power supply to signal processing systems. The broad range offered by Würth Elektronik includes various types and innovative technologies and allows developers and engineers to find tailored solutions for their specific requirements. The latest addition, the aluminium hybrid polymer capacitors, combines the properties of aluminium electrolytic capacitors and polymer capacitors. Combining technological expertise with high-quality materials results in durable and reliable products.

With a clear understanding of the factors that affect the lifespan and performance of these capacitors, you can ensure that your designs deliver optimal results even under demanding conditions.