Electrolytic Capacitors: Are They Obsolete or Here to Stay?

Despite the growing availability of alternative capacitor technologies, such as hybrids, electrolytic capacitors remain the optimal choice for a wide range of applications. Their enhanced performance, long lifespan, and cost-effectiveness solidify their position as the preferred solution among designers. However, the availability of these capacitors is increasingly restricted, as some manufacturers issue End of Life (EOL) notifications for specific form factors, particularly through-hole technologies (THT).

Electrolytic capacitors: core technology at Panasonic Industry

Aluminum electrolytic capacitors offer a higher capacitance-to-volume ratio compared to ceramic capacitors, which is a significant advantage in many scenarios. They are commonly used to smooth voltage fluctuations, filter noise, and amplify audio frequencies.

In recent years, however, polymer-based and hybrid polymer capacitors have emerged, offering certain advantages over traditional electrolytic capacitors. These benefits include longer lifespans, higher maximum operating temperatures, improved stability, reduced equivalent series resistance (ESR), and safer failure modes.

Despite these advancements, many design engineers continue to prefer traditional electrolytic capacitors. The primary reason is their cost efficiency, particularly in applications where space is not a concern. Additionally, specific applications, such as power supplies, rely on through-hole components to achieve cost savings.

Although surface mount technology (SMT) appears dominant, especially in power supplies, the inclusion of magnetic components often necessitates through-hole mounting for mechanical stability. Consequently, PCBs frequently need to accommodate both SMT and THT components, reducing the choice between through-hole or surface-mounted capacitors to component pricing, provided performance is comparable.

Concerns have arisen as some manufacturers announce the discontinuation of through-hole electrolytic capacitors in certain package sizes. Panasonic Industry, however, takes a different approach, viewing electrolytic capacitors as a core technology. The company continues to invest in research, development, and expanded production capacities. For through-hole (THT/PTH) components, Panasonic commits to offering all package sizes and capacitance values in its portfolio for the foreseeable future.

High-performance through-hole electrolytic capacitors from Panasonic

Panasonic’s FR and FS series are prime examples of high-performance through-hole electrolytic capacitors. The EEU-FR series, spanning from 6.3 to 100 VDC, offers capacitance values from 4.7 to 8200µF in package sizes ranging from Ø5×11 to Ø16x25mm.

These capacitors boast a lifespan of 10,000 hours, operate at temperatures up to 105°C, exhibit low ESR, and demonstrate robust ripple current capabilities. The EEU-FS series, also ranging from 6.3 to 100 VDC, delivers capacitance values from 27µF to 10,000µF while optimizing space requirements, potentially reducing the number of capacitors needed within the same package size.

While through-hole electrolytic capacitors remain in demand, modern designs predominantly utilize surface-mounted (SMT) components due to their smaller form factor and easier automation. Therefore, most research and development efforts focus on SMT components, where Panasonic leads the market.

A significant trend is the extension of capacitor lifespans to align with global sustainability movements. Under its GREEN IMPACT initiative, Panasonic is committed to achieving net-zero CO2 emissions across its operations by 2030.

This commitment aligns with its vision for 2050, aimed at reducing CO2 emissions throughout society by promoting energy-efficient products and green energy technologies. Durable components play a crucial role in sustainable operations by decreasing the need for frequent replacements.

Particularly in applications like remote monitoring and small cellular base stations, components with extended lifespans are essential due to difficult accessibility and costly downtime.

Panasonic’s FH series offers the longest lifespan for surface-mounted electrolytic capacitors in its class. It ranges from 6.3 to 100 V and provides capacitance values from 10 to 680µF in package sizes from Ø6×7.7h to Ø10x10mm, with a lifespan of 10,000 hours at 105°C—3,000 hours (> 40%) longer than most competitors.

Competitors that match this lifespan cannot provide comparable capacitance or temperature ratings, underscoring Panasonic’s superiority. Furthermore, the FH series minimizes ESR and delivers high ripple current ratings, aligning with Panasonic’s commitment to superior performance in its electrolytic capacitor lineup.

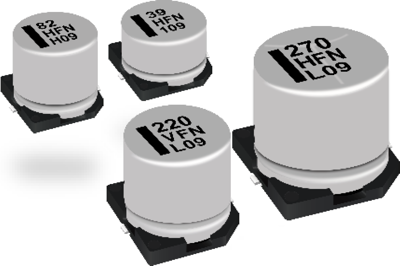

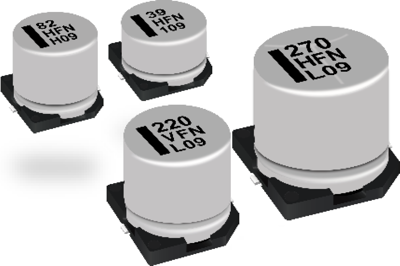

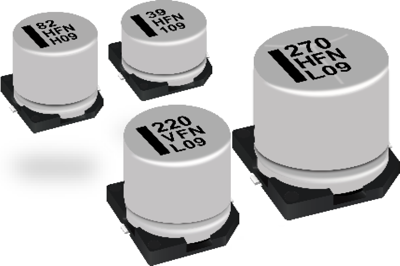

FN Series: Innovative Solutions for Modern Applications

Panasonic’s new FN series stands out with several remarkable features:

- these capacitors are one to two sizes smaller than other low ESR electrolytic capacitors on the market, making them ideal for space-constrained applications.

- With capacitance values that are 20% to 80% higher than the previous FK series, the FN series offers engineers more flexibility, especially in high-capacitance applications.

- Additionally, the FN series covers a broad voltage range from 6.3V to 100V, including variants from 6.3V to 50V specifically designed for high-temperature placement without solder, making them compatible with modern manufacturing processes.

Moreover, FN capacitors feature low ESR, enhancing their performance in applications with high ripple currents, which is particularly important in switch-mode power supplies. For applications requiring mechanical stability, the FN series offers vibration-resistant options that ensure reliability even in demanding environments. Finally, the FN series complies with RoHS regulations and meets AEC-Q200 standards, making them suitable for automotive and industrial applications where reliability and safety are essential.

Electrolytic capacitors: an indispensable technology

Electrolytic capacitors remain an indispensable technology in the electronics industry, despite emerging alternatives. They offer numerous advantages, including high capacitance, cost efficiency, and longevity.

Panasonic continues to invest in this technology, focusing on the development and production of innovative series like the FN series, which impresses with miniaturization, high capacitance, low ESR, and vibration resistance. These advancements ensure the future of electrolytic capacitors and their place in the technology market.