Hidden Details: Successful Micro Soldering with Metcal

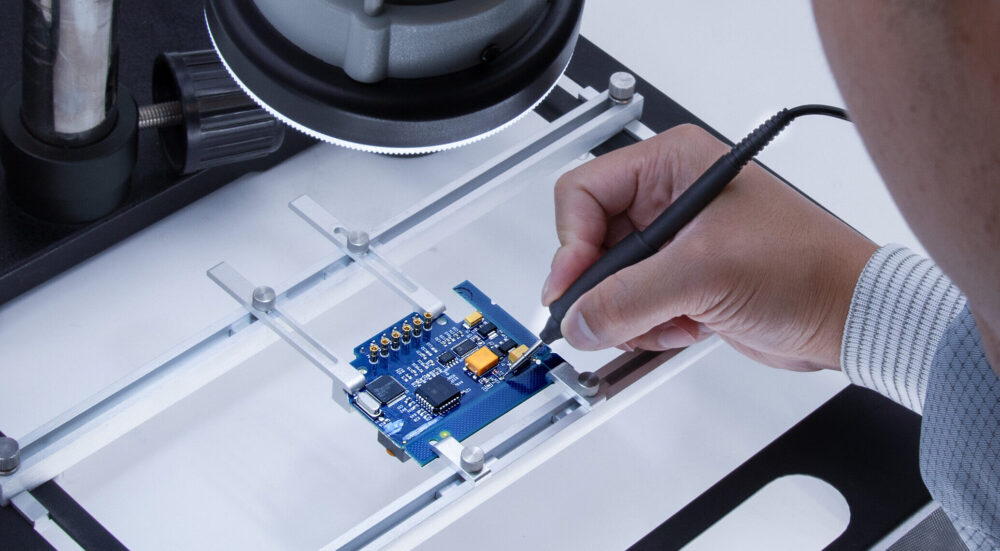

Micro soldering is a highly specialised technique that is becoming increasingly important in the modern electronics and repair industries. Soldering at a microscopic level requires utmost precision to create reliable electrical connections. In this article, we take a closer look at micro soldering, its applications, and the advantages of working under a microscope.

What is Micro Soldering?

Micro soldering refers to the process of soldering very small components and circuit boards, where precise handling and fine techniques are essential. This specialised soldering method is commonly used in electronics manufacturing. In micro soldering, specific tools and equipment are utilised to ensure the creation of precise connections at extraordinarily small scales. The solder joints are often in the micrometre range, and even the tiniest errors can lead to malfunctions.

Why Solder Under a Microscope?

Soldering under a microscope offers a new dimension of precision. Here’s why this technique is crucial:

- Precision: Observing small components under a microscope allows for accurate placement and soldering of these tiny parts.

- Enhanced Visibility: The magnification of components and solder joints enables the detection of even the smallest details, helping to minimise errors.

- Easier Handling: With the right tools, even complex tasks can be performed with greater ease, providing a better sense of where and how to apply the solder.

- Miniaturisation: Micro soldering under a microscope is essential for the trend towards miniaturisation in electronics manufacturing. The demand for smaller devices with higher performance is set to continue. Innovations in micromechanical systems and nanotechnology are also advancing micro soldering to a new level.

Diverse Applications of Micro Soldering

The applications of micro soldering are extensive. This soldering technique is often used for the repair of electronic devices, allowing damaged or defective components on circuit boards to be replaced or repaired—especially relevant for smartphones, tablets, and medical devices.

Micro soldering is also crucial in the development of microsystems, such as sensors and actuators, meeting the demands of miniaturisation.

In scientific research and product development, micro soldering is employed to create prototypes or functional miniature devices.

The Right Tools for Micro Soldering

When working under a microscope, the field of view is significantly restricted. Additionally, components and circuit boards provide limited contact surfaces in micro soldering applications. Accurate temperature control is vital to prevent damage to components or connection points. Therefore, selecting the right tools is critical. These tools not only enhance precision but also facilitate the handling of delicate components. For such precise work, tools must have the following characteristics:

- Compact

- Lightweight

- Well-balanced

- Powerful

The MicroFine product series from the renowned manufacturer Metcal exhibits all these qualities. Designed specifically for use under a microscope, these are the smallest tools in the manufacturer’s product range.

Metcal MicroFine: The Smallest Tools for Microscope Work

The MicroFine product series includes the smallest handpieces and tweezers from Metcal to date. The advantages of these products are:

- lightweight and ergonomic

- SmartHeat™ technology for high-performance soldering

- smallest diameters and geometries down to 0.1 mm for MFTC and MFT soldering tips

- compatible with all MX and CV soldering systems

- hands-free insertion and removal of the tip possible

- hands-free alignment of the tweezers’ tip

- ideal for handling micro components down to 01005

With the lightweight, well-balanced, and compact tools from the MicroFine product series, you can fully leverage the efficiency and precision of your existing MX and CV soldering systems under a microscope.

MicroFine Handpieces for MX and CV Soldering Systems

The MicroFine handpieces for MX and CV soldering systems, particularly the MX-H9-MFH and CV-H9-MFH models, offer an exceptional combination of lightness and ergonomics. Weighing less than 12 g and measuring just 115 mm in length, they are perfectly balanced and easy to handle. For added comfort, the grip padding can be easily changed. The cable thickness of only 3.5 mm allows for effortless handling, while the 2-metre cable provides excellent flexibility.

A practical workstation facilitates hands-free insertion and removal of the tip, as well as the storage of soldering tips. Numerous tip sizes are available, including fine versions with diameters down to 0.1 mm. The tips come in various geometries, including chisel, conical, and bent forms, allowing for versatile applications in micro soldering technology.

MicroFine Tweezers for MX and CV Soldering Systems

The MicroFine tweezers for MX and CV soldering systems, particularly the MX-H10-MFT and CV-H10-MFT models, are renowned for their high precision and user-friendliness. With adjustable tip alignment, they can effortlessly handle horizontal distances from 1206 to 01005. Weighing less than 30 g and only 98 mm long, they fit comfortably in the hand and allow for ergonomic handling. The cable-friendly design, with a thickness of just 3.5 mm, contributes to easy handling, while the flexible 2-metre cable offers additional versatility.

A practical workstation supports hands-free insertion, removal, and alignment of the tip, also providing convenient storage for soldering tips. With numerous available tip sizes, including fine variations down to 0.1 mm, and different geometries such as chisel, power wedge/blade, and bent tips, these tweezers offer an excellent solution for the needs of micro soldering technology.