How to optimise production with SMT spacer bolts

SMD spacer bolts are the key to precise production. Spacer pins specially developed for automatic placement with pick-and-place machines can enable considerable time and cost savings. We explain and present products that can be used to optimise production.

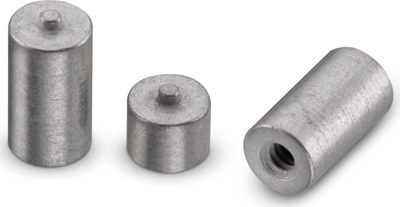

What are spacer bolts?

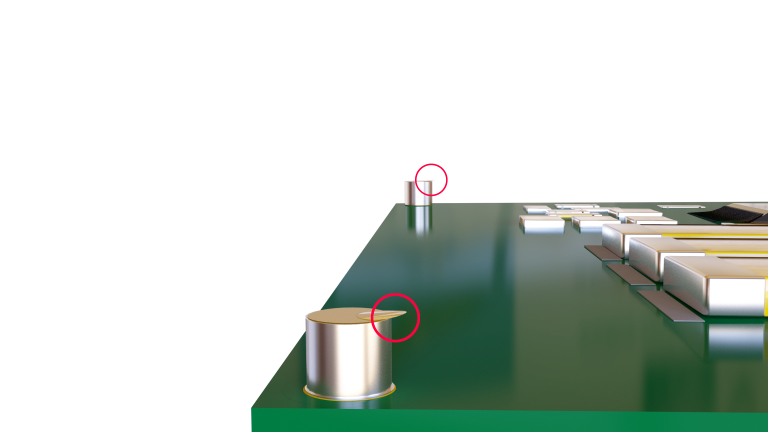

Spacer bolts create reliable connections and precise distances between electronic components. Depending on the intended use, the spacers are made from materials such as steel, brass or polyamide. Other features include the length of the studs and the thread dimensions.

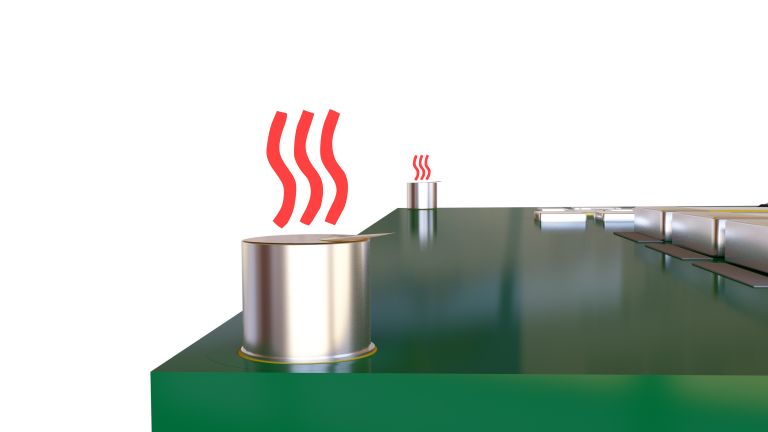

The selection of a suitable bolt depends on the mechanical load and the heat dissipation of the overall system.

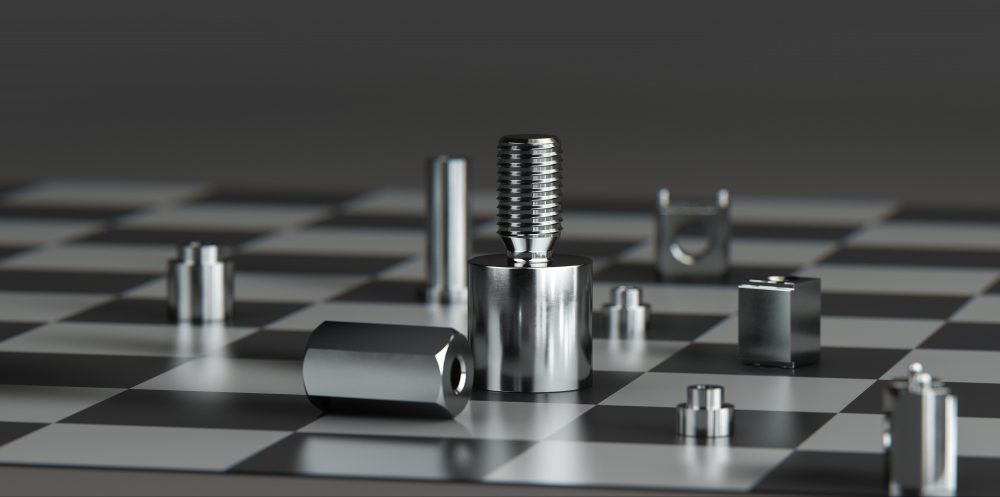

The role of spacer bolts in electronics production

Spacer bolts play a decisive role in electronics production. These small components are indispensable for positioning electronic components safely and precisely. The use of spacer bolts with internal threads made from high-quality materials such as brass or other metals not only ensures stability, but also longevity in the manufacturing processes.

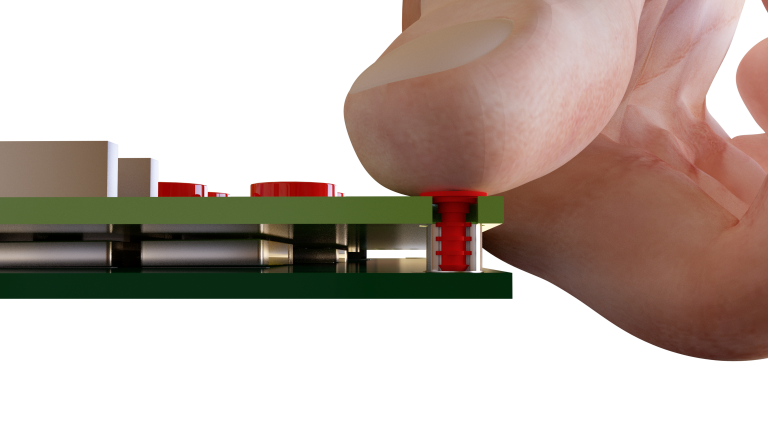

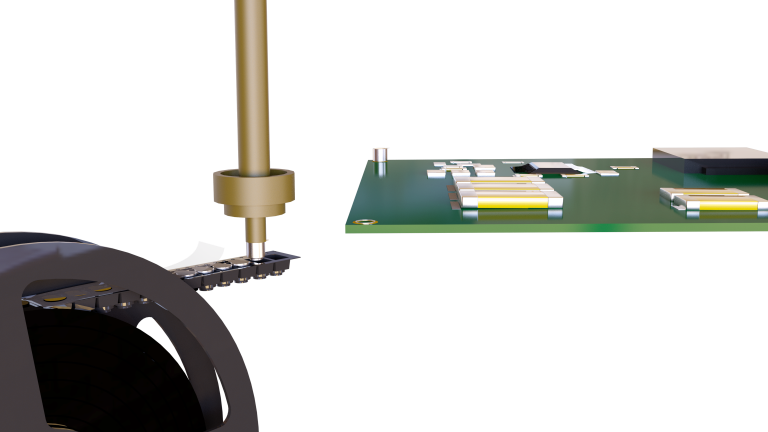

While the manual assembly of components in electronics production takes a lot of time, automatic placement machines can position the components in a matter of seconds. The higher the quantities to be processed, the greater the time and cost savings. The prerequisite: components should be used that have been specially prepared for pick-and-place machines.

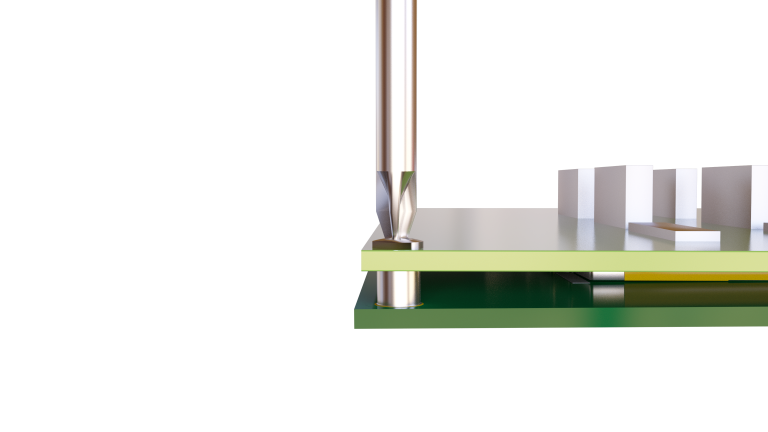

Optimise production with SMT spacers for full automation

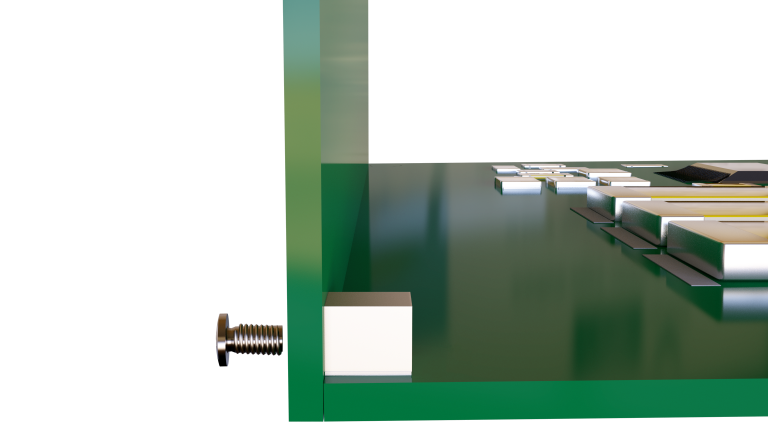

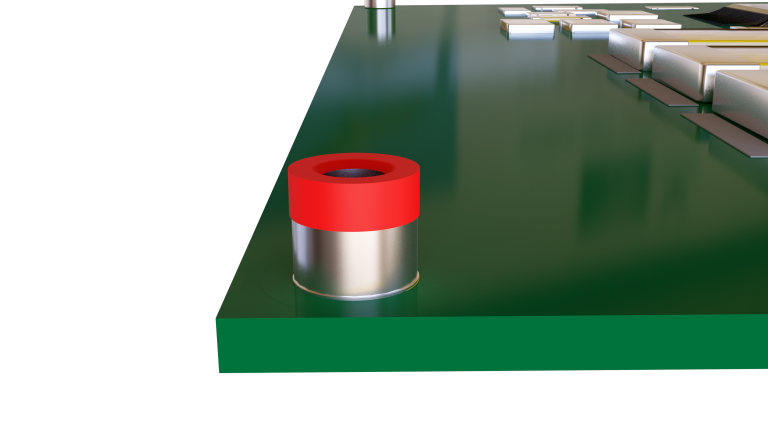

The SMT spacers from Würth Elektronik significantly optimise the placement process of electromechanical assemblies. The SMT spacers have been specially developed for automatic assembly and can absorb high holding forces and torques. While the assembly of conventional spacer pins is very time-consuming, the SMT spacers are ideal for full automation:

- They are available on rollers.

- They can be positioned very precisely on the PCB.

- Different versions cover a wide range of applications.

- They ensure fast, strong and secure solder connections.

Special features of SMT spacers

Applications of SMT spacers

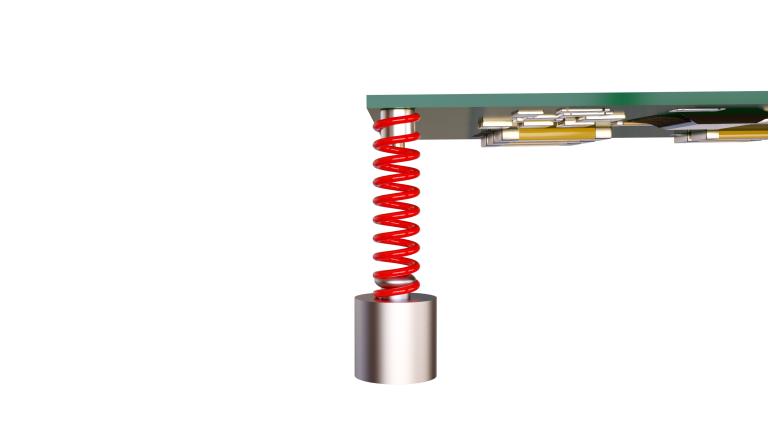

Spacer bolts and contact fingers for the automotive industry

Spacer bolts also play a decisive role in the automotive industry. In addition to the usual properties of spacers, the automotive industry requires a robust fastening solution that can withstand vibrations and temperature fluctuations.

With its WE-SCFA and WA-SMSA products, Würth Elektronik offers spacer pins and contact fingers that are produced in accordance with IATF-16949. Both product series are easy to solder and can be assembled automatically – ideal for high-volume production.

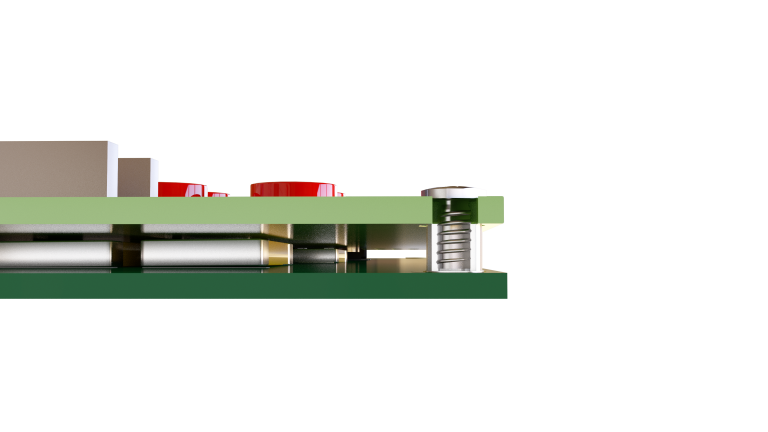

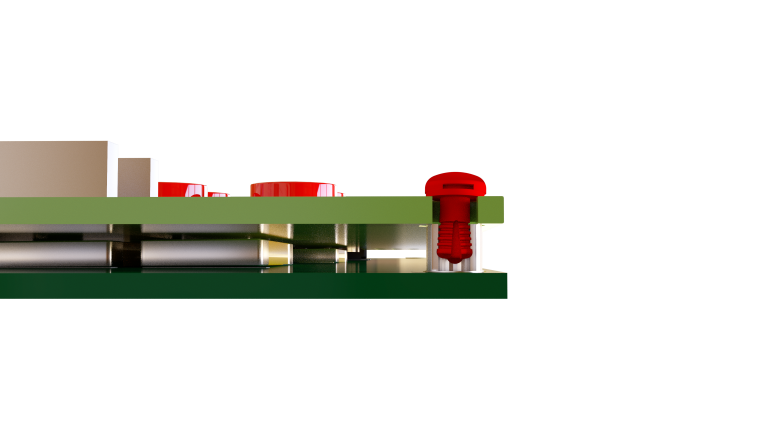

The SMT mountable board-to-board connectors WA-SMSA are made of tin-plated steel and enable distances of 1 to 15 mm between PCBs or PCBs and housings. They impress with strong holding forces and torques and have a polyimide film as a suction surface for the placement head, which is easy to remove. WA-SMSA is optionally available with a through-hole and M3 thread.

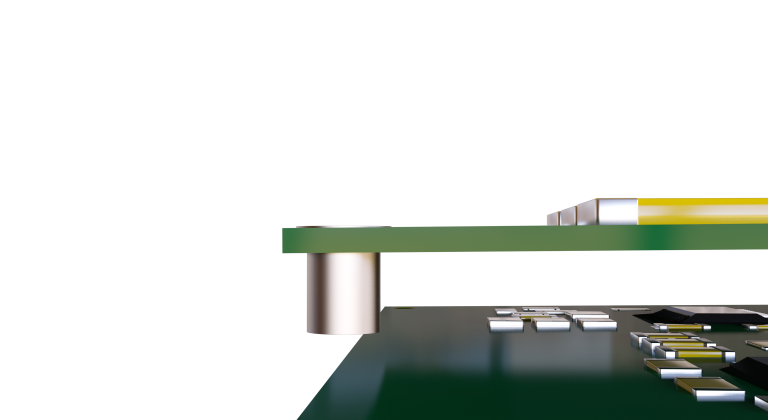

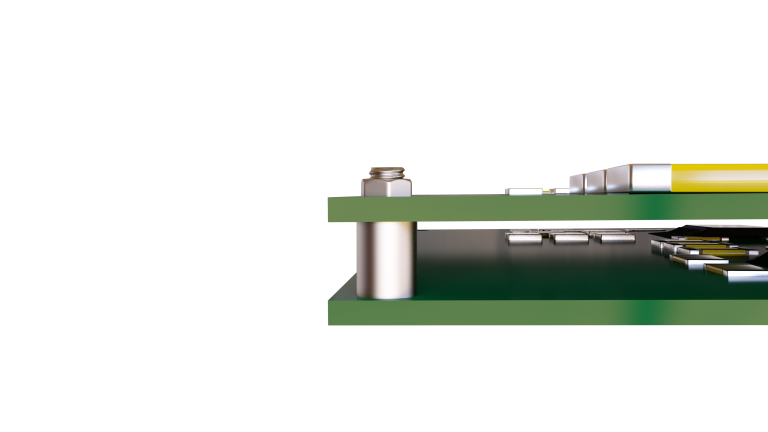

The WE-SCFA contact fingers also come from IATF 16949-certified production. They offer an elegant solution for creating a reliable ground contact. The flexible clamps made of gold-plated copper-beryllium are extremely resistant to mechanical and temperature-related stresses and are available in 17 different versions.

Design kits containing the different product variants are also available for developers.