Requirements for Connectors: IP Protection Classes, Transmission Rates, Mating Cycles & Co.

Wherever electronic devices are used, and networks are created, plug connectors are in use. Connectors and connectors must therefore meet different requirements: Reliability, robustness and durability are relevant prerequisites for high safety and economic effectiveness. What types are there, and what influences must they withstand?

What are connectors?

Connectors are electromechanical components for connecting and disconnecting electrical conductors. They consist of two “sexes” – the female component known as the receptacle and the male counterpart known as the plug. By joining the two components together, a circuit is created. This can be closed and opened by means of plugs.

Power supply, data exchange and more: connectors come in a variety of configurations and can be found in numerous applications. Many examples can be found: for example, in power transmission, data exchange or in the transmission of audio-visual information. To ensure performance-efficient use, connectors must meet defined requirements. After all, they are exposed to permanent environmental influences. Vibrations, mechanical loads, the effects of liquids (for example, solvents, oils, or chemicals) and corrosion all put a strain on the service life of these electromechanical components.

What types of connectors are there? What requirements do they have to meet, and how do environmental influences affect the components?

Different types of connectors

- Audio connectors and video connectors: are used to transmit audio and video signals. These types of connectors are often installed in devices for home use (for example, in headphones or in the TV).

- High-frequency connectors: RF connectors (cable, plug and socket) are usually shielded against electromagnetic interference by a mesh. A coaxial conductor is often used for wiring because its internal insulation is suitable.

- IC sockets and IC sockets: In prototype development, integrated circuits (ICs) are usually connected by IC sockets. This allows a fast and flexible exchange of components.

- Industrial connectors: are characterized by high mechanical robustness and are used for the transmission of control signals in industrial applications (for example in the automotive sector).

- Card sockets: are soldered directly onto the circuit board of an electronic device and allow the use of SIM cards, SD or MicroSD cards.

- Laboratory connectors: for fast, safe, and uncomplicated connections in sensitive work areas (for example, banana plugs or alligator clips).

- Power connectors: enable the connection of cables and devices to power networks. Mains connectors are available straight, angled, as three-pole type with protective contact or as two-pole Euro plug for electrical appliances with housing.

- Board-to-board connectors: used in the assembly of printed circuit boards. Typical connectors for boards are male connectors, female connectors, pin boards or socket connectors .

- Telecommunication and data technology connectors: most common network connectors are RJ plugs and sockets. RJ45 connectors are used in Ethernet networks, for example, where they connect routers and gateways.

- Connecting terminal, terminal block and single-wire connector: enable cable wires and strands to be connected quickly and easily. Stripped cables can be plugged in and removed without tools – practical for prototyping.

What environmental influences must connectors withstand?

Resistance to: Vibrations & mechanical stresses

Shock, tensile and compressive loads have a negative impact on the service life of connectors. Contact connections become loose, or detach completely, due to regular mechanical stress. Housings can break, causing failures of entire systems.

It is therefore essential that the electromechanical components withstand external environmental influences (e.g., vibrations) and that they can be used without problems.

Different materials and designs ensure greater resistance to vibrations and mechanical loads – particularly relevant in industrial systems. In this respect, industrial connectors must be particularly robust and comply with a higher insulation level (for example, insulation group C according to VDE 0110).

Resistance to: magnetic influences

To prevent magnetic interference, connectors (both plug and socket) can be equipped with a shield. This must be adapted to the intensity of the magnetic interference (for example, dynamic, power or field-bound interference). In case of heavy electronic load, the entire path of the plug (including cable) may also be insulated.

Shielding to preserve other electrical components is important because: Several magnetic fields are generated in electronic devices by the current flow. Depending on their intensity, these fields can cause damage to other components. The result is interference in the entire circuit. Furthermore, the components can be permanently damaged and have to be replaced.

Electromagnetic shielding follows the principle of induction – the use of electrically conductive materials (for example copper or aluminium) succeeds in suppressing magnetic interference. To protect other electronic components, the components, connectors, or housings are shielded with protective foils or covered with metallic paint.

Resistance to: Liquids, Corrosion, Chemicals & Foreign Substances

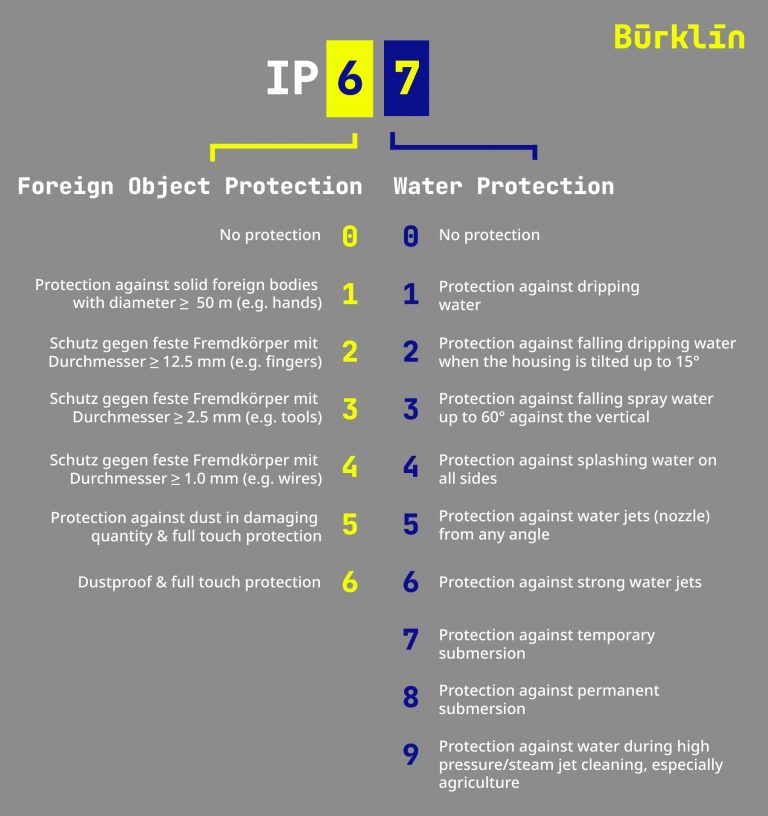

Connectors must be able to withstand various influences (such as those caused by liquids or chemicals) in accordance with the respective area of application (for example, in industrial plants). Depending on the degree of stress and the requirements of the application, the electromechanical components are assigned to corresponding IP protection classes. The abbreviation “IP” stands for “International Protection”. The following code numbers provide information on which requirements the products meet.

Connectors for the exchange of data & audio-visual signals as well as for power transmission

As versatile as the application areas of connectors are, their designs and structural characteristics are equally varied – whether it’s Quick lock couplings for fast and secure connection and disconnection of circuits, or IC sockets in prototype development.

The decisive factor is that the connectors meet the respective requirements in terms of mating cycles, resistance, and economic effectiveness. The various connector types are identified and available in the Bürklin Elektronik online store.