UL, CSA, HAR or VDE: Cables and Wires for International Use

Standards such as HAR, VDE, UL, and CSA play a crucial role in the deployment of cables and wires within their respective markets. Strict adherence to these specific standards is essential to ensure compliance for use in industrial facilities and machinery. In this article, we will explore the various standards and their significance. Additionally, we will introduce the HELUKABEL FIVENORM cables that are specifically designed for global use.

Overview of Key International Standards: UL, CSA, HAR, and VDE

Cables and wires are governed by standards that are vital for ensuring safety, quality, and interoperability in international markets. Standards such as HAR, VDE, UL, and CSA define specific requirements that products must meet to be accepted and utilised. These standards are not only important for commercial purposes but also significantly enhance consumer safety.

UL: Underwriters Laboratories

UL is a global testing organisation based in the USA that establishes safety standards for a wide range of products, including cables and wires.

The UL standard primarily focuses on the safety and flammability of products. Cables that receive UL certification have undergone rigorous testing to ensure their suitability for the North American market.

For manufacturers intending to sell their products in the USA and Canada, UL certification is crucial, as it is often a legal requirement.

CSA: Canadian Standards Association

The CSA standard is the Canadian benchmark issued by the Canadian Standards Association. Similar to the UL standard, it sets safety requirements for electrical products, including cables and wires.

The CSA certification serves as an important quality mark for products sold in Canada, ensuring they meet the specific safety requirements and tests mandated for the Canadian market. Cables with CSA certification are designed to meet the highest safety standards to protect users.

Key UL and CSA Standards for Cables and Wires

UL and CSA test according to the same harmonised standards of the Canadian Electrical Code (CEC) and the National Electrical Code (NEC), making their certifications essentially interchangeable. Here, we briefly outline the key standards for cables and wires:

- UL AWM and CSA AWN: Appliance Wiring Material (AWM) includes a broad category of wires and cables available in various constructions. Underwriters Laboratories (UL) classifies AWM as a recognised component that can be used in listed or classified products.

- UL MTW / CSA TEW: American (MTW) and Canadian (TEW) cables feature either bare or tinned copper conductors with PVC insulation. They are moisture-resistant and pass the VW-1 flammability test. UL 1028 is suitable for wiring machine tools, equipment, control cabinets, electronic circuits, and switchboards. These cables operate within a temperature range of up to 105 °C and have a rated voltage of 600 V.

HAR: Harmonised Approval Mark

The HAR standard, also known as the “Harmonised Approval Mark,” is a certification standard that applies to cables and wires used in Europe. It was established to ensure uniform quality assurance for electrical products and to facilitate the free movement of goods within the EU.

Products bearing the HAR mark comply with European safety standards and are thus approved for utilisation in various applications within the EU. The standard sets requirements for flammability, mechanical strength, and safety attributes to guarantee that cables and wires function reliably in diverse environments.

VDE: Association for Electrical, Electronic & Information Technologies

The VDE standard is a German standard issued by the eponymous testing organisation. This standard encompasses both safety and functional regulations for electrical installations and products.

As part of the VDE certification process, cables and wires are tested for safety and compatibility with existing electrical systems. Products that bear the VDE mark thus offer enhanced safety and reliability, especially in Germany and other European countries. The VDE standard is particularly vital for applications in both domestic and industrial settings.

Global Compatibility of Cables: Why Standards Matter

In an increasingly globalised economy, compliance with various standards is crucial to securing the international competitiveness of products.

Cables and wires that meet multiple standards can be deployed in diverse markets. This compliance ensures that products fulfil uniform safety standards and performance requirements across country and continental borders.

Interoperability — the ability of products to function seamlessly together — is particularly significant in industrial and construction sectors. Companies are increasingly opting for systems that operate not only locally but also internationally. By adhering to multiple standards, manufacturers can guarantee that their cables and wires can be effortlessly utilised in various applications, whether in Germany, the USA, or Canada.

HELUKABEL FIVENORM: Versatile Cable Solutions for Diverse Markets

Machinery and plant engineers, who market their products internationally, often face the challenge that each target market has its own standards and regulations that all incorporated components must comply with. This can lead to increased inventory requirements, as many components are certified according to only a single standard. For machinery sold in Europe, America, and Asia, this might mean that multiple variants of the same component are necessary.

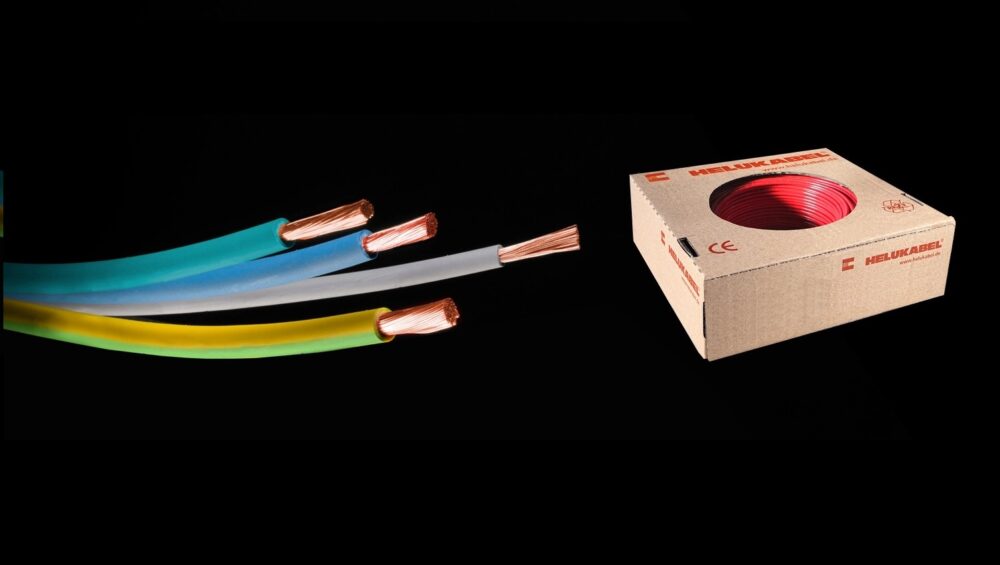

For wiring, HELUKABEL offers a straightforward and economical solution with its FIVENORM stranded wires. These copper cables with PVC insulation are certified according to all common approvals such as VDE, CSA, EAC, and UL MTW, making them suitable for global use.

The certifications according to HAR, UL AWM, UL MTW, CSA AWM, and CSA TEW enable economical inventory management and simplification of bill of materials. Thanks to the MTW (Machine Tool Wiring) listing, the FIVENORM single-core cables are ideally suited for comprehensive machinery construction. Export-oriented companies thus benefit from more efficient inventory management and simplified bill of material administration.

Produced in Germany under the highest quality standards, the FIVENORM single-core cables are available in a variety of colours. The materials used in manufacturing are silicone- and cadmium-free, and free from substances that hinder paint wetting.

For smaller conductor cross-sections (0.5 – 6 mm²), HELUKABEL offers these not only in reels but also in practical 100-metre ring boxes. This facilitates handling for lower requirements and simplifies wiring for machinery. Users also enjoy the advantages of a maximum conductor temperature of 90 °C and an expanded voltage range of up to 1,000 volts AC and 1,250 volts DC.