Energy Management with Modular Energy Measurement Technology

Nowadays, energy management not only plays an important role for the environment and society, but is also a decisive factor in competition. Only companies that can control their energy consumption can reduce costs and increase their efficiency. The right energy management plays a key role here. Read our blog post to find out what you need to look out for and which devices can help.

How does energy management work?

Energy management is used to identify and implement opportunities to save energy. The energy sources and streams in the business are recorded and analyzed. Based on the results of the analysis, suggestions for improvement are developed, economically evaluated and then implemented. Measuring devices and systems that record energy consumption can therefore support the effective use of energy and thus save costs. Data transparency is particularly important. It is essential to record, consolidate and visualize data from all areas of the company, for example to set up safety measures to protect plant and machinery.

In order to achieve a long-term increase in energy efficiency, companies define an energy policy strategy and measure their progress using key performance indicators. In addition to investment decisions regarding energy efficiency, energy-relevant processes are defined and the necessary organizational structures are adapted.

Standards for energy management systems

The international standards ISO 50001 and ISO 50005 were especially created for energy management systems. The aim of ISO 50001 is to continuously improve existing energy efficiency. The standard includes specifications for systematic energy management, including requirements and instructions for the application of energy management systems in companies and other organizations. The ISO 50001 standard also aims to achieve the following objectives:

- Tapping into new energy efficiency potential

- Savings in energy costs

- Reduction of greenhouse gases, e.g. CO2 emissions

- Reduction of other environmental impacts due to energy consumption

The ISO 50005 standard is based on ISO 50001 and comprises a step-by-step process for energy management. The standard aimes specifically at small and medium-sized companies. More requirements and elements are added at each stage. It forms a basis for subsequent further development up to the level of ISO 50001.

Standard-compliant energy management with expandable system solutions

In addition to standards that are constantly evolving, the technical framework is also changing. New possibilities for data acquisition and communication standards such as OPC UA simplify the networking of various devices. In order to implement a standard-compliant energy management system that can respond to such new requirements, it is helpful to rely on easily expandable and combinable system solutions.

The manufacturer Janitza specializes in innovative solutions in the field of network monitoring, energy data acquisition and digital built-in measuring devices. Janitza’s energy measuring devices are available in different versions and help to fulfill the complex regulations. In combination with the GridVis® grid visualization software, Janitza’s products form an integrated system environment for managing energy data and monitoring power quality, load management and residual current monitoring. This enables a holistic solution that meets the requirements for energy efficiency, sustainability, availability and safety.

Modular products for efficient energy management from Janitza

By using energy measurement devices from Janitza, such as the UMG 801 or the UMG 96 series, important energy data can be recorded. This data provides a solid basis for current and future challenges. The measurement data from all devices can be saved, visualized and analyzed in the corresponding software.

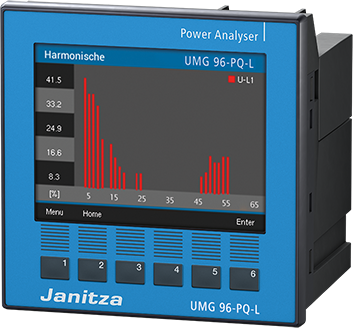

Efficient energy monitoring for new and existing systems with the UMG 96 network analyzer

The UMG 96-PQ-L-LP grid analyzer from Janitza records detailed power quality events and can show the current and voltage curve directly on the display. Due to the possibility of connecting low-power converters and Rogowski coils, the measuring device is perfect for installation in new or existing systems.

Whether energy monitoring, power quality analysis or residual current and temperature monitoring – the UMG 96-PO-L-LP offers functions for each of these applications. With this device, you can identify potential savings and avoid system failures at the same time.

The use of low-power measurement inputs allows the application of more compact and often less expensive devices compared to conventional current transformers. The energy-saving transformers work with millivolt voltages on the secondary side, which means that no additional disconnect terminals are required for the connection.

To provide a simple solution for retrofit applications, passive Rogowski coils can be used in combination with a network analyzer. In this case, the measurement device itself takes over the function of the measurement transducer, which saves both costs and valuable space in the control cabinet.

The UMG 96-PQ-L-LP is a modular mains analyzer that is able to measure full-wave events and show them directly on the display. It also has a large memory capacity, thanks to special data compression, which can be used for several years. Even with high-resolution power quality measurement, the long storage time for current, power and work is retained.

All relevant information can be conveniently displayed, graphically represented and analyzed on the color graphic display of the UMG 96-PQ-L-LP. It is also possible to configure the comparator individually or using predefined comparison profiles.

The device can be easily extended with an Ethernet interface, 2 residual current inputs and a temperature input using a plug-in extension module. By using the Ethernet module, up to 30 simple MID energy meters of type B23 312-10J can also be connected as slave devices.