PV Systems: How Connection Technology helps save Energy

However, quality and compatibility are extremely important, especially for PV cables and PV connectors. How the use of high-quality, compatible plug-in elements helps to save energy and costs? Learn more about this in the magazine article!

Table of contents

In light of the current supply crises, the discussion surrounding the topic of renewable energies has flared up again. In addition to wind and water power, solar energy is the most popular in Germany. Thousands and thousands of tiny technical components ensure that photovoltaic systems function properly and supply energy in a cost-saving manner.

As with many other product categories, operators and companies are confronted with price increases in the area of PV components and solutions. The reaction is to increasingly use low-cost products – often without considering their quality. The associated costs are usually not considered from the beginning.

Connection technology: unexploited potential

Underestimated and yet so crucial: Why is connection technology of particular importance in terms of energy consumption and cost savings?

Basically, high-quality connection technology ensures that current can flow continuously, safely and without interference. The diameter of the cables used plays an important role in this. After all, the closer the cables are to the inverter of the system, the more current flows through them. Important in this context: The more current flows through the individual lines, however, the larger the cross-section of the respective cores must be.

Problems arise when a line in the PV system is designed too thin. This is because the current flow and the electrical resistance cause heat loss. This means that a huge amount of unused energy is lost over a period of several decades.

Length and cross-section of cables and lines for PV systems

Professional engineers have already provided concrete examples of calculations in this regard. In the case of a one-meter-long copper cable with a cross-section of 2.5 square millimeters, a typical string current of 8.5 amperes generates a thermal output of approximately 360 megawatts. If you extrapolate this supposedly small amount over a service life of 20 years, you get a value of 20 kilowatt hours for just one meter of copper line.

Assuming that the operator could sell the electricity for 0.05 euros, he would lose one euro on this one meter of line. If you consider the size of some PV systems and the number and length of the lines that are installed within them, it is clear that there is enormous potential for savings here, which could easily be exploited. After all, if you double the cross-section of the cable, the costs are halved.

What potential do high-quality connectors offer?

Recent studies also show that in the area of connectors in particular, high energy losses – and thus additional costs – can occur if the connector components in question are of poor quality. Not only is there a constant stream of reports of defective products causing system failures. Studies have also shown that heat loss can increase up to tenfold if inferior or non-compatible components are used.

It is therefore generally not advisable to use supposedly compatible connectors from different manufacturers. Even if the manufacturer points out compatibility with the industry standard, the principle that applies to the matching of connection technology components is: everything from a single source. In the long run, this investment pays off in any case!

Minimize energy losses through secure cable nodes

Concrete measures can also be implemented in the area of cable management to optimize operations. One example: Among other things, Y-distributors are installed in PV systems in order to combine lines into a collective line. Here, sources of error can arise in the flow of current.

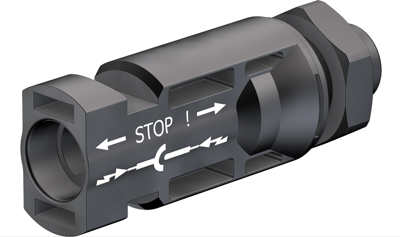

Special fuses ensure that the system is protected against damaging reverse currents. In the area of cabling, the compatibility of the products used also plays a major role in optimally aligning the system, avoiding sources of error and actively combating energy losses.

Reliable monitoring with an energy management system

In the worst case, faulty components result in the failure of individual connections and systems. With the help of a professional energy management system with appropriate software, sources of error can be located and eliminated relatively quickly – an investment that is basically worth its weight in gold for monitoring and controlling the plant.

Saving energy with the right technology

In the area of cables, cabling and connector systems, it is clear that investing in high-quality, coordinated products pays off in every case. Not only to ensure the flawless operation of PV systems, but above all to counteract energy losses. Low outgoing power and minimal service effort – a goal that can certainly be achieved with the right connection systems!

Bürklin Elektronik offers a wide range of high-quality PV connection technology products from top manufacturers! Individual models can be easily found in our online store and ordered immediately!bIf you have any questions about our range and specific products, please contact the experts at Bürklin Elektronik at any time! We will be happy to advise you.