Crimping Solar Cables – How to Make the Perfect Connection

Find out how you can connect your solar system perfectly with the right technology and the right tools. We will show you step by step how to make professional crimp connections and thus ensure a safe and efficient power supply. Be inspired by the special features of solar cable crimping and use our expert knowledge for your next project!

Table of contents

Efficient installation: special tools for photovoltaic systems

The installation and maintenance of photovoltaic systems require special tools to meet the technical requirements. It is particularly important to crimp solar connectors and solar cables precisely using suitable crimping pliers in order to create standard-compliant electrical connections. These special tools play a crucial role in the safe and efficient installation of photovoltaic systems.

The demand for such installations is constantly increasing as more and more people are turning to sustainable energy sources. The electrical trade must therefore have the right equipment to meet the high demands. This is the only way to install high-quality systems that guarantee long-term electricity production.

The use of professional tools such as crimping pliers and crimping dies not only improves safety, but also increases the efficiency of the work. Careful handling of these special tools is essential for the successful installation and maintenance of photovoltaic systems.

With an increased focus on renewable energies, special tools for the installation and maintenance of photovoltaic systems are becoming indispensable. They enable the electrical trade to successfully implement challenging projects and make a contribution to the energy transition.

Materials for crimping solar cables

Certain tools and aids are required for crimping solar cables in order to achieve a high-quality result. The most important tools include crimping pliers with suitable inserts for the various cable diameters, stripping tools for stripping the cable and a quality testing device for checking the crimp connections. A number of quality features should be met when purchasing the materials:

- Robust material: The crimping pliers should be made of robust material and have an ergonomic handle to enable fatigue-free working. The inserts should be precisely machined to produce clean and secure crimp connections.

- UV-resistant solar cables: It is also important to use high-quality solar cables that are UV-resistant and have a high temperature resistance. This ensures that the solar system functions optimally even under extreme conditions. The length and cross-section also play an important role.

Perfect connection: how to proceed when crimping solar cables

When installing and maintaining a PV system, it is crucial that the cables and connectors are crimped correctly. This is the only way to guarantee perfect functionality. High-quality special tools help to avoid potential sources of error. Perfect, high-performance connections can be created in just a few steps:

- crimping solar cables requires precision and care. First, the cable must be stripped according to the manufacturer’s instructions. It is important that no wire strands are damaged and that they lie neatly on top of each other.

- In the next step, the appropriate plug is plugged onto the exposed end of the cable and fixed in place. All connections should then be checked again.

This method not only ensures a reliable power supply to the photovoltaic system, but also helps to extend its service life.

Avoid mistakes: Tips for crimping solar cables

When crimping solar cables, there are a few special features that differ from conventional cables. Firstly, the material of the solar cables is specially designed for use in photovoltaic systems and is therefore more resistant to environmental influences such as UV radiation and moisture. When crimping, care should be taken to ensure that the crimping tools used are also suitable for such special cables in order to establish a proper connection.

To avoid errors when crimping, it is important to proceed carefully and follow the manufacturer’s instructions exactly. Care should also be taken to ensure that the cable ends are stripped cleanly to ensure good contact. Another tip is to practice on a test piece before actually crimping to get a feel for the process.

Overall, crimping solar cables therefore requires a little more attention and care than with conventional cables. However, with the right preparation and technology, high-quality connections can be made that last a long time and ensure smooth operation of the photovoltaic system.

Special tools for the installation and maintenance of photovoltaic systems from Knipex

Crimping solar cables: The new tool case for photovoltaic professionals

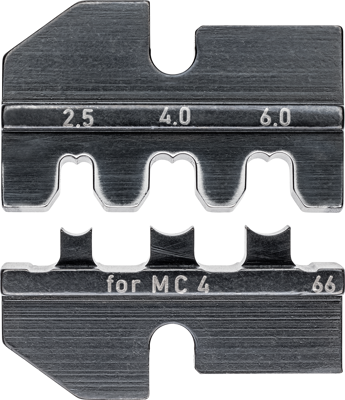

If you’re looking for a tool set specifically designed for working on MC4 solar connectors, the Photovoltaic Tool Case 97 91 04 V01 from KNIPEX could be just what you’re looking for. This 7-piece set offers a variety of tools, including precision wire strippers, cable shears and crimping system pliers, to complete your tasks efficiently and accurately. In addition, the case contains a crimping insert specially developed for MC4 solar connectors and an impact-resistant plastic box for safe storage. The tool case from KNIPEX offers optimum support for the installation and maintenance of PV systems.

The Knipex basic hand pliers: Perfection for a wide range of crimping applications

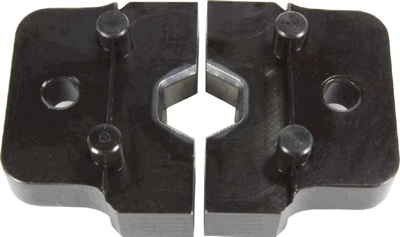

The crimping system pliers for interchangeable crimping dies (97 43 200) from Knipex are an indispensable tool for professionals, characterized by their versatility and precision. With an extensive range of suitable crimping dies, including the MC4 (Multi-Contact) PV connectors used for photovoltaic installations, it offers a solution for almost 1,000 crimping applications.

The assembly tool is already included in the scope of delivery and additional crimping dies can be purchased separately. The system pliers enable almost parallel crimping movements and guarantee consistently high crimp quality thanks to precision inserts and an unlockable positive lock.

Compared to the widely used scissor principle, crimping pliers with parallel closing jaws offer major advantages. They prevent the connector from twisting during the crimping process and guarantee that the flanks are rolled in symmetrically. This is particularly important for terminals that have to be processed in an F-crimp profile.

Ergonomically shaped handles and force amplification through lever transmission ensure fatigue-free working and make the Knipex basic hand pliers an indispensable professional tool for precise and reliable crimping applications.

Do you have any questions about crimping solar cables?

The connection of solar cables is crucial for the efficiency and safety of your system, so it is important to familiarize yourself with the materials and special features of crimping. If you have any questions or require further information, please do not hesitate to use our digital contact form. We will be happy to help you.

Would you like to understand what is behind solar technology? Find out more here!