The Digital Twin in Electronics – A Comprehensive Guide

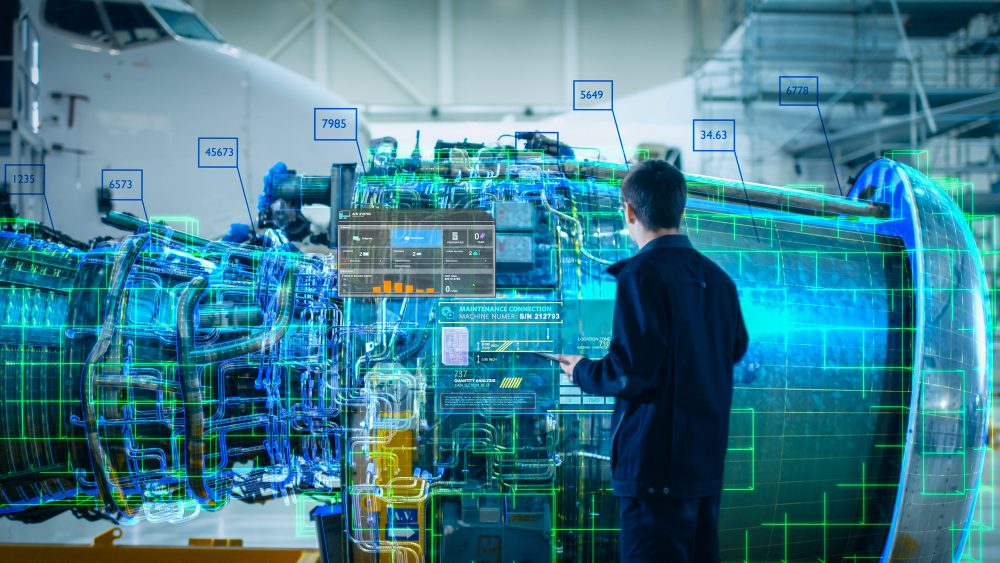

Advancing digitalization and the integration of Industry 4.0 technologies have a firm grip on the diverse landscape of the electronics industry. One of the key concepts that is becoming increasingly important in this context is the digital twin. This technology offers the opportunity to plan and optimize development and production processes efficiently and also to raise the maintenance of products and systems to a new level.

Table of contents

A definition of the digital twin

A digital twin is a virtual representation of an object or system. The aspects represented can be material or immaterial. This digital copy uses real-time data to create and update an exact copy of the physical original. With the help of such a digital image, the entire life cycle of individual components as well as complete devices and even entire production lines can be significantly optimized in electronics development.

What is the purpose of the digital twin in the electronics industry?

The implementation of digital twins in electronics manufacturing perfects the way products are designed, produced and maintained. By using digital twins, developers and engineers can simulate, analyze and optimize complex systems – without physical prototypes. This not only saves time and resources, but also enables a more detailed and accurate analysis of design decisions and planning steps.

Time savings in planning and design

With the help of the digital twin, unprecedented precision and efficiency can already be achieved in the planning and process design phase. Development teams can simulate electronic components and entire systems in a fully controlled virtual environment, significantly reducing the need for physical prototypes. Such scenario tests help to identify and correct potential design errors at an early stage. This leads to a significant shortening of development cycles.

Useful advantages in production

In the production phase, digital twins make a decisive contribution to automation and increasing efficiency. This is because the detailed replication of production lines allows companies to identify potential bottlenecks and inefficiencies before they lead to real problems. Planned adjustments to the production process can be tested and validated virtually using the digital twin – a huge advantage in terms of rapid implementation and reducing downtime.

Optimized maintenance processes

Digital twins also support quality control by enabling continuous monitoring and adjustment of production parameters. This ensures compliance with quality standards and makes predictive maintenance feasible.

- The continuous analysis of operating data by the digital twin reveals patterns that indicate impending failures or problems.

- Maintenance teams can intervene proactively and carry out maintenance work in a targeted and efficient manner.

- Downtimes are reduced and the service life of electronic systems is extended – leading to significant cost savings and greater customer satisfaction.

How does a digital twin work?

The core of a digital twin is based on seamless integration and the analysis of large amounts of data that accompany the physical object throughout its lifecycle. The way this technology works can be broken down into several key components:

Data integration as a foundation and basic framework

The basis for creating any digital twin is the use of reliable data. This involves collecting real-time information through sensors, chips, RFDI modules and other data collection technologies. This includes operational information, performance data of the physical object as well as environmental values that reflect its operating conditions.

These can be temperature fluctuations and weather factors, for example. They influence the performance of machines and devices and must therefore be taken into account in the design, for example when selecting materials.

Composition of the digital model

Once the key data sets have been collected, the next step is modeling. In this step, the collected information is used to create a highly detailed virtual simulation of the physical object. ECAD models, for example, are used for this, which enable a precise representation of electronic components and circuits. Such tools are essential for accurately simulating complex electromechanical interactions within the digital twin.

Bürklin Elektronik services already offer ready-made ECAD models with which you can mime circuit diagrams and arrange components on a virtual circuit board, among other things. This enables you to create the perfect PCB design quickly and free of charge – configured entirely according to your personal wishes and requirements.

Original and digital copy in harmony

Subsequent extensions and modifications can also be processed in the digital twin using data collected from the ongoing operation of the real machine. The result: optimizations along all stages of the value chain, from planning to retrofitting.

The digital twin in combination with AI and machine learning

AI and machine learning do not stop at the functionality of the digital twin. The trendy concept of artificial intelligence can be used to drive the further development and smooth operation of digital twins. By intelligently analyzing the collected data, these technologies recognize patterns, predict future conditions and proactively identify potential malfunctions or failures.

Optimized enclosure construction using digital twins

Digitalization approaches promote profitable business – in the long term. Enclosure construction, a critical process within electronics production, benefits significantly from the introduction of a digital twin. As the heart of many industrial and commercial electronic systems, control cabinets place high demands on safety and functionality. Their complexity requires efficient design. The virtual image provided by a digital twin offers valuable advantages in this respect:

- Virtual prototyping: enables the optimum arrangement of components to be identified at an early stage without the need for physical prototypes.

- Simulation of heat distribution: supports the precise prediction and avoidance of overheating problems to ensure the longevity of components.

- Reduction of development time: the development process is accelerated through virtual testing, resulting in a significant increase in efficiency.

- Early error detection: Design errors are minimized through early identification and correction, which improves product quality.

- Increased design flexibility: offers improved adaptability to changing design requirements through agile development methods.

Profitable progress with Bürklin Elektronik

When it comes to digital transformation or making existing processes more economical and efficient, Bürklin Elektronik is your professional partner. With a wide range of products from renowned quality manufacturers, we enrich your plant, your business and each of your projects. Visit our online store with its wide range of products and use the practical filter elements to quickly navigate to your desired item!