Electromagnetic Compatibility in Industry 4.0: The Key to Smooth Production Processes

Industry 4.0 is changing the way we produce and work. The integration of intelligent systems, the Internet of Things (IoT) and networked machines is creating highly automated and networked production environments. This transformation promises greater efficiency, productivity and flexibility. However, it also brings new challenges, especially in the area of electromagnetic compatibility (EMC). But what exactly is EMC – and what do you need to pay attention to in order to ensure the availability and reliability of production facilities?

Table of contents

What is electromagnetic compatibility (EMC)?

EMC is the ability of an electronic device to function in its electromagnetic environment without itself causing interference or being affected by external interference. This property is of crucial importance in ensuring that equipment continues to function in increasingly complex production environments.

The basics of electromagnetic compatibility

Electromagnetic compatibility has two main aspects: emission and immunity. These two factors are crucial to avoiding interference in an environment where many electronic systems are operated in close proximity to each other.

- Emission refers to the unwanted electromagnetic fields that a device emits.

- Interference immunity describes the ability of a device to continue to function properly in the presence of electromagnetic interference.

What EMC standards are there?

There are numerous EMC standards worldwide that are designed to ensure that devices do not emit interfering electromagnetic fields. Standards such as the IEC 61000 series provide specific guidelines for industrial devices to ensure a high level of immunity to interference and low levels of emitted interference. Compliance with these standards, as well as the regular inspection and certification of all devices and systems, make a significant contribution to ensuring EMC.

Challenges of EMC in Industry 4.0

Industry 4.0 is characterised by the networking of machines, sensors, robots and IT systems. This networking in the manufacturing industry leads to an increased density of electronic devices, which constantly increases the risk of electromagnetic interference. Furthermore, the increasing complexity of automation solutions brings with it an increasing number of powerful actuators and sensitive signals.

The most common challenges in the context of Industry 4.0 include:

- Interference from wireless communication: In smart factories, wireless technologies such as WLAN, Bluetooth and ZigBee are often used. These can cause mutual interference.

- High-frequency interference: Machines that operate at high frequencies can generate strong electromagnetic fields that interfere with other devices.

- Static discharges: Static discharges occasionally occur in production environments, damaging sensitive electronics or impairing their function.

Strategies for improving EMC in Industry 4.0

Improving electromagnetic compatibility in such complex environments requires careful planning and implementation of EMC strategies. Moreover, companies must continuously adapt their EMC strategies to keep pace with technological developments. This is the only way to prevent production downtime and quality problems. The most important strategies in this context include:

- Design optimisation: EMC aspects should be taken into account as early as the planning phase for devices and systems. This includes the selection of suitable materials, the layout of printed circuit boards and the minimisation of loop areas that could act as antennas.

- Shielding: The use of shielding materials and housings that can block or reduce electromagnetic fields also plays an important role in terms of EMC. They prevent the leakage of interference fields and protect sensitive areas from external interference.

- Filters: The use of filters at various interfaces has also proven effective in suppressing high-frequency interference.

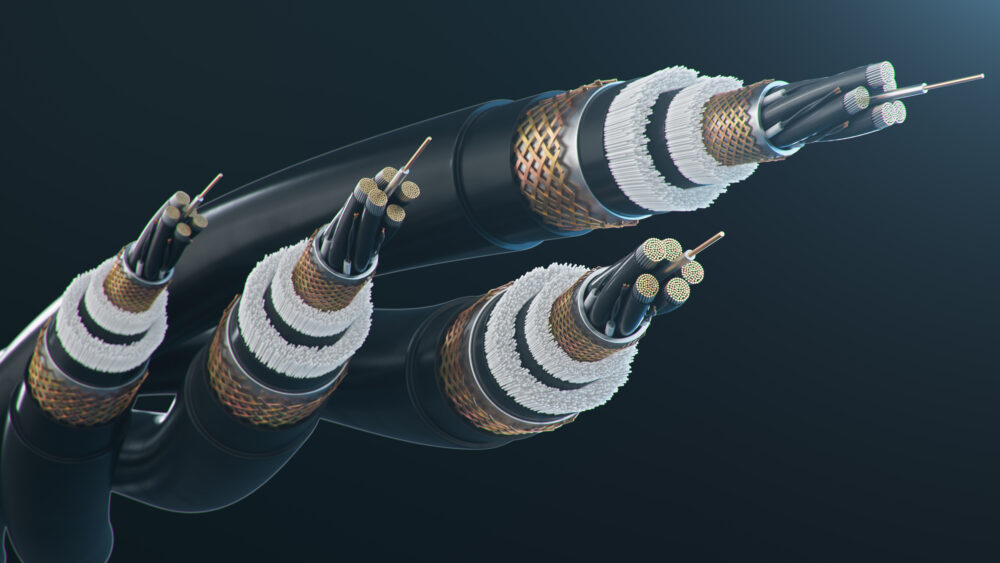

- Earthing and cabling: Correct earthing and proper cabling are essential to minimise the risk of interference currents.

- Simulations and tests: It is also advisable to use simulation software to predict EMC problems and to carry out extensive tests to ensure compliance with EMC requirements.

The role of connectors in EMC

Connectors play a central role in ensuring electromagnetic compatibility in industrial applications. As passive electromagnetic components, they are not covered by the EMC Directive and are not subject to CE marking. However, they are often the interfaces through which interference enters or leaves systems.

The choice of the right connectors and their correct application are therefore crucial for a robust EMC strategy. The transfer impedance and the shielding attenuation are considered to be the central criteria for evaluating the EMC properties of connectors:

- The transfer impedance is particularly important when it comes to minimising the interference currents passing through the shield. The lower the transfer impedance, the better the shielding.

- The shielding attenuation indicates how much of the electromagnetic energy is blocked by the shield. A high shielding attenuation means better shielding efficiency.

EMC-optimised connectors

Filter connectors combine standardised connection mechanisms with integrated EMI/RFI suppression components. These block electromagnetic interference directly at the source. The result: more space available on the printed circuit board and less weight compared to separate filters.

EMC-optimised connectors and their fields of application:

- Filtered D-Sub connectors are often used in data communication and industrial control systems to minimise electromagnetic interference.

- Feedthrough filters are used, for example, in control cabinets, where they protect industrial control and regulation systems from external electromagnetic interference. In communication systems, feedthrough filters improve signal quality by suppressing high-frequency noise and other interference.

The future of EMC in Industry 4.0

As Industry 4.0 continues to evolve and new technologies such as 5G, IoT and artificial intelligence (AI) are introduced, the importance of EMC will continue to grow. Organisations will need to continually adapt their EMC strategies to keep pace with technological developments. Future trends could include

- Intelligent EMC solutions: development of adaptive filters and dynamic shielding that automatically adjust to changing electromagnetic environments.

- Collaborative robotics: integration of EMC considerations into the development of collaborative robots (cobots) that work side by side with human workers.

- Smart sensors: Use of sensors that not only record production data but also monitor the electromagnetic environment and report faults in real time.

Success factor Electromagnetic Compatibility

As you can see, electromagnetic compatibility is a critical success factor for the implementation of Industry 4.0. Companies that plan their EMC strategies comprehensively and at an early stage can minimise disruptions, increase the reliability of their systems and ultimately strengthen their competitiveness.