Quality in Equipment and Mechanical Engineering: Basis for Smooth Processes

In times when energy- and cost-efficient solutions are sought in virtually every area, the desire for long-lasting and robust products and components is once again increasingly noticeable in equipment and mechanical engineering. We think: with good reason! But what is connected with the demand for quality? How do high-quality products influence the production process? And: What guidelines must be observed? In the magazine article, we offer answers to these important questions. Read more!

Why quality is important in equipment and mechanical engineering

Whether in industry, on construction sites or even in your own workshop: Smooth operation is the primary objective when dealing with machines and technical equipment. The quality of the products used and their components has a direct impact on the flow of production processes. Frequent failures or longer downtimes often have their origin in components of inferior quality and are a cost trap for operators that should not be underestimated. After all, in production, time is money.

Maintenance and repair costs could be kept low by using high-quality products in this area. In addition, flawlessly processed and first-class components stand for longevity and robustness. Particularly in the industrial context and with a view to the challenges of Industry 4.0, it is important to increasingly consider parameters such as resistance and durability.

What characterizes high-quality products and services in equipment and mechanical engineering?

When we talk about quality in the production of components for equipment and mechanical engineering, we are referring to specific product characteristics. In this context, it should be noted: First-class products are characterized above all by the fact that they meet extremely high standards from conception to production and undergo various tests and inspection procedures – more on this later.

The main characteristics of high-quality components are:

- performance

- top materials

- robustness

- reliability

- long durability or longevity

- simple, efficient assembly

It is also clear that, depending on the component and product category, some of these characteristics are more important than others. Especially for products such as rocker switches, subminiature toggle switches, pushbuttons, tactile switches or even emergency stop buttons, user-friendliness is a key quality criterion. In the industrial context, in turn, the focus is on the robustness and resistance of the components. Reliability and safety play important roles for control cabinet components – you can read more about these topics in our magazine article “Control cabinet – safety first”.

Approaches to quality products and services

To ensure quality, products pass through specific steps in the development and manufacturing process. In this process, compliance with quality standards is important to ensure that finished products meet the highest standards.

DIN EN ISO 9001: Cornerstone for quality assurance

Precise specifications and stringent quality controls throughout the entire product life cycle are essential. Quality management systems are of great importance in this context. With ISO 9001 systems, manufacturers enjoy numerous advantages that affect both the quality of their products and their corporate image.

The advantages at a glance:

- Quality Assurance

- Productivity increase

- Increased competitiveness

- Reduction of costs by optimizing processes and avoiding errors

- Risk minimization

- Image enhancement

By using advanced methods such as Six Sigma or Lean Manufacturing, manufacturers also strive for continuous improvement in order to offer ever better products. For some product groups, such as connectors, the compatibility of the individual models is also a decisive factor in addition to the quality of the products – in this respect, too, processes can be optimized and costs saved. Using the example of PV connectors, we looked at how parameters such as compatibility and quality help to save energy and reduce costs – read more in the magazine article.

Smooth processes thanks to high-quality components

Quality ensures smooth processes in industry or on construction sites and similar. Thanks to their robustness and durability, first-class products can save valuable time and – in production – a lot of money. Parameters that define high-quality components are:

- performance

- the use of top materials

- robustness

- reliability

- long durability or longevity

- simple and efficient assembly

With a standardized quality management system, companies and plants can count on many other advantages besides quality control, which also improve the company image – a win-win situation for producers and end users.

Bürklin Elektronik: Top service and advice

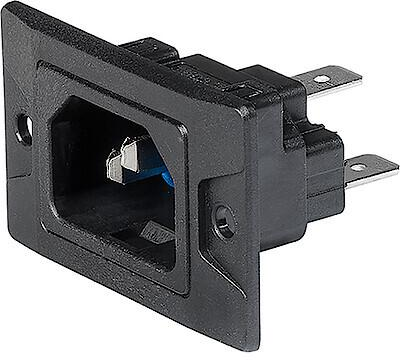

In the Bürklin Elektronik online store, we offer first-class products from our top manufacturers. From switch cabinets to hot air blowers, buttons and switches to connectors or wires: In the field of equipment and mechanical engineering, our partner companies pay attention to the highest quality standards – from the design of individual components to production.

Do you have questions about individual products or models? Do not hesitate and contact our experts! We will be happy to advise you.