Safety in Equipment and Mechanical Engineering

In the complex segment of equipment and mechanical engineering, the safety factor plays a central role alongside quality and usability. Depending on the type of equipment and area of application, specific legal requirements apply to the production and use of electronic components. We offer you an overview of legal requirements, mandatory standards and the significance of various safety-relevant components. We accompany you on the way to more reliability and risk prevention in the modern construction of electronic systems.

Legal requirements and standards

Strict safety regulations apply to equipment and mechanical engineering. These legal frameworks ensure a reliable, high standard of quality in the manufacturing and commissioning of equipment and machinery. Primarily, they serve to protect workers, increase consumer confidence and minimize the general risk of danger and liability. In addition, uniform EU-wide safety requirements lead to comprehensive regulation and harmonization of the product range on the sales market – distortions of competition are reduced. Below you will find a selection of legislation and legal standards for the German-speaking countries.

Safety-relevant laws in mechanical engineering

- Product Safety Act (ProdSG): The ProdSG sets out basic safety requirements for products offered on the German market. This obliges manufacturing companies to take safety-relevant factors into account in the design, production and marketing of machinery and equipment.

- Machinery Directive (RL 2006/42/EC): This is a European legal regulation that sets essential requirements for the safety of machinery. Manufacturers must comply with these strict requirements and submit an EC declaration of conformity. This is a mandatory document that serves as proof of compliance with all statutory safety aspects.

- Industrial Safety Ordinance (BetrSichV): In addition to the handling of machines and products, the protection of personnel health is also regulated by law. The Ordinance on Industrial Safety and Health therefore sets out the legal framework for the use of machinery and equipment in companies. The ordinance also requires employers to assess potential risks and implement necessary protective measures.

Machine safety standards

- DIN EN ISO 12100: This international standard sets out safety principles for the design and construction of machinery. Its purpose is to protect people working with a particular piece of equipment from any hazards and risks and to prevent occupational accidents. Manufacturers are also supported in assessing risks and taking suitable protective measures.

- DIN EN 61508: This standard specifies guidelines for the functional safety of electrical, electronic and programmable systems. Possible malfunctions in any process, from conception to decommissioning, are identified, thus ensuring reliable functionality throughout the entire life cycle.

- DIN EN 60204-1: This standard is used as soon as machines have electrical equipment. It is specifically geared to the electrical equipment of machines, specifies safety requirements and contributes to operational safety.

- DIN EN 13849-1: This standard focuses on the safety of control systems – also in mechanical engineering. Safety criteria are named and guidelines are provided, namely for the design of safety-related control system components, including software.

Safety-related components in equipment and mechanical engineering

Individual components, sophisticated safety mechanisms, distributors as well as various signal transmitters and pushbuttons: Many cogs can be turned to increase safety in plant engineering.

In the Bürklin Elektronik online store, for example, you can obtain first-class fuses and electromagnetically compatible components for equipment protection from the manufacturer Schurter.

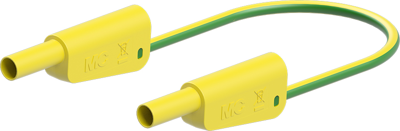

Stäubli products can also be used to ensure compliance with the IEC-61010 measurement category: This is an international standard, among other things, for classifying overvoltage resistance. Schneider Electric in turn offers solid-state relays, industrial relays as well as interface relays that can be mounted safely, flexibly and in a space-saving manner.

From emergency stop buttons and connection plugs to power supply modules and potential distributors to soldering irons and entire supply units: Bürklin Elektronik is at the service of safe equipment and mechanical engineering.

Signal transmitters and their importance in mechanical engineering

In equipment and mechanical engineering, rapid fault detection is indispensable. If faults are detected too late, this can lead to far-reaching damage to production, and the plant itself and the personnel responsible can also be put at considerable risk. Acoustic as well as optical signaling devices belong to particularly important safety components and are also affected by the standard DIN EN 60204-1. They quickly and insistently draw attention to sources of error or to measured values that have been exceeded or fallen short of. Are you still looking for suitable products? In the Bürklin Elektronik online store you will find high-quality audio signaling devices and optical signaling devices from the renowned manufacturer Werma.

Many products lead to a significant reduction in hazards, bring about greater usability and positively influence the quality of the end products in many ways. You can read more about this in the corresponding magazine articles in our device construction and mechanical engineering series.

Usability in Mechanical Engineering Quality in Mechanical Engineering

Maximum safety with the Bürklin Electronics Service

Do you want to be at the top of your game when it comes to safety, and are you in need of competent additional advice or support for special concerns? Bürklin Elektronik is a reliable partner for you in all these matters. Browse the professional range in our online store and click your way through the numerous security solutions! Or get expert help from our trained service team: We look forward to hearing from you and receiving your inquiries!