Control Cabinet: Safety first

Complex in design and essential for smooth operation in industry and business: the control cabinet. To protect electrical components, electronic devices and, above all, people, certain safety precautions must be taken during initial operation and maintenance. Which safety standards apply when building or installing a control cabinet? And: What needs to be considered when maintaining control cabinets?

What needs to be considered when maintaining control cabinets?

Switch cabinets must meet a large number of legal requirements in order to be approved. The applicable standards must, of course, be complied with without exception when building or installing control cabinets. Two standards in particular are mandatory for control cabinet designers and manufacturers: the IEC 60204-1 standard for protection of electrical equipment for machines and IEC 61439 for low-voltage switchgear and assemblies.

In Germany, control cabinets must be equipped with EMC shielding, among other things, to counteract various interference factors. In addition, grounding and lightning protection must be ensured. And finally, the control cabinet must also be secured against manipulation and overvoltage.

In addition, only special components are used in the construction or installation of a control cabinet, which have been manufactured for the specific conditions in terms of robustness and resistance.

Components in control cabinet construction

All products that are installed in control cabinets have been designed by the respective manufacturer for very specific environmental conditions. For example, the individual components must be adapted to the ambient temperature. But the heat dissipation of the individual components must also be taken into account during installation. In addition, the individual components must be reliably protected from external influences.

The products should be optimally attuned to each other in order to ensure the continuous power supply of the plant. Special industrial relays for the separation of low-voltage and load circuits provide additional protection against overvoltage, electric arcs and, as a consequence, against operational accidents with personal injury.

Cable management & cabling in the control cabinet

Loose cables are an absolute no-go in control cabinets. Tidy and secure cable management not only simplifies any (maintenance) work. It also reliably prevents damage to cables and wires. Wire clamps help to organize and easily handle cables and wires. Special mounting blocks guide control cabinet cables into orderly paths – thanks to dedicated wiring channels. In this context, it must be ensured that cables and wires are not damaged by sharp edges.

Quality always means more safety. When purchasing cables, wires and power connections, attention should be paid to quality and robustness – as with all control cabinet components. Flame-retardant and oil-resistant stranded wires or touch-proof control cabinet sockets are manufactured for the special circumstances and thus guarantee more safety.

Thermal management in the control cabinet

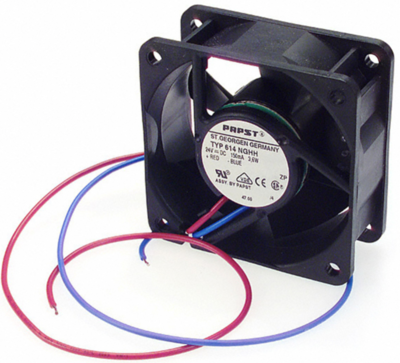

Overheating in the control cabinet not only threatens to shut down the system. It can also result in damage to the circuit board or device. Reliable thermal management is therefore essential, especially in industry. This includes enclosure heaters and thermostats, but also special axial and radial fans. The latter have a high degree of efficiency, work efficiently and reliably regulate the ambient temperature.

Lighting in the control cabinet

When it comes to control cabinet lighting, it is essential to invest in products that illuminate the control cabinet as a whole. Recommended in this context: models with high-quality optics and prismatics. These also illuminate the lower third of the cabinet. Thanks to magnetic technology, these quality products can be installed without tools if desired.

In addition to the actual control cabinet lighting, investments should be made in good signal lights to ensure safety.

Signal lights: Safety status at a glance

It is not without reason that signal lights are required by law in industry, but also in safety environments. The advantage: the acoustic and visual signals allow workers to quickly gain an impression of the current situation or the system’s condition. In this sense, special signaling technology for control cabinets with visual and audible signaling devices ensures greater safety. In companies and industry, signal lights are therefore considered safety-relevant products.

In the Bürklin Elektronik online store you will find LED lights, buzzers, sirens and warning lights, as well as compact signal towers from various top manufacturers.

Emergency Stop Buttons

Mandatory in every industrial plant: the emergency stop button. In the event of problems or error messages in the control cabinet area, it is essential to be able to stop production with the emergency stop button until the problem at the control cabinet has been rectified.

The demands on products in this category are manageable, but all the more important for that:

- good visibility

- simple operation

- high functionality

Maintenance, testing & servicing of the control cabinet

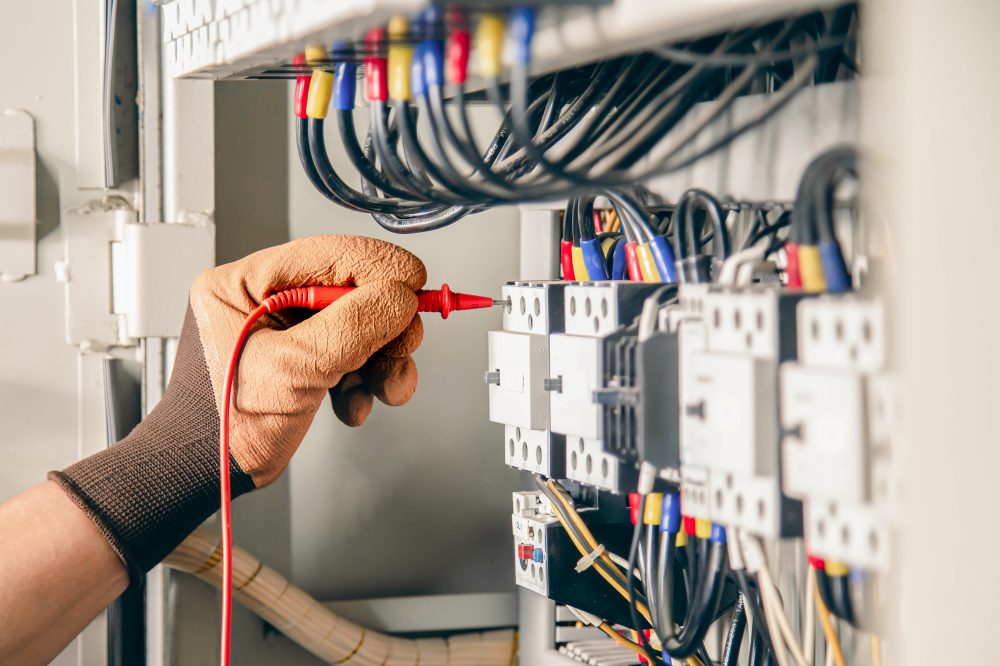

To ensure the continued safety of control cabinets, regular inspections and maintenance must be performed. Irregular maintenance intervals can have serious and also expensive consequences: In addition to the risk of overheating, electricity faults are also possible. Consequential damage such as a fire, the failure of entire plants or even industrial accidents with personal injury must be avoided.

Basically, the maintenance or servicing of control cabinets is required by law. Various measurement technology for the control cabinet and measurement accessories for safe and precise measurement, testing and checking of voltages are also essential components of the maintenance process. When it comes to current clamps, multimeters and similar devices, it is essential to invest in high-quality products.

Bürklin Elektronik focuses on quality products from top manufacturers such as C&K, Finder, Knipex, Lapp, Panduit, Phoenix Contact, Wago, Werma and Wiha.

Product innovations that check for absence of voltage, such as the VeriSafe series from Panduit, show that extensive know-how and many resources are being used on the manufacturer side for the development of innovative models. The goal: ensuring even greater safety and risk reduction. Practical in this context: Compliance with legal regulations is simplified by such products.

Safety thanks to high-quality tools and accessories

Safety first when working on the switch cabinet. Special VDE screwdrivers and pliers, control cabinet wrenches and sockets are specially made for working in the control cabinet. Here, too, it is important to pay attention to quality when selecting tools and, depending on the activity, special protective clothing such as gloves should be worn.

Bürklin Elektronik has a broad product portfolio in the field of tools and socket strips – discover the top products from our manufacturing partners now!