What you need to know about VDE standards

We encounter standards in almost every area of life and they primarily serve to guarantee defined norms. The VDE standards specifically are a range of guidelines in terms of technical safety. They help to ensure that the basic requirements for mechanical protection and health in electrical installations are met and thus make a decisive contribution to the prevention of electrical accidents.

Table of contents

- Definition: What are VDE standards?

- VDE standards, the law or voluntary action?

- The creators of DIN-VDE standards

- Types and fields of application of VDE standards

- The most important VDE standards in overview

- Local scope of the VDE standards

- When do VDE standards become applicable?

- Buy VDE-certified tools at Bürklin Elektronik

Definition: What are VDE standards?

VDE standards are technical regulations that define safety requirements, test procedures and other specific criteria for products and systems in the field of electrical engineering, electronics and information technology. They serve as pioneering standards and aim to ensure the safety, efficiency and compatibility of electrical installations. Essentially, they define minimum requirements for equipment and processes in order to guarantee the best possible protection for users, consumers and the environment.

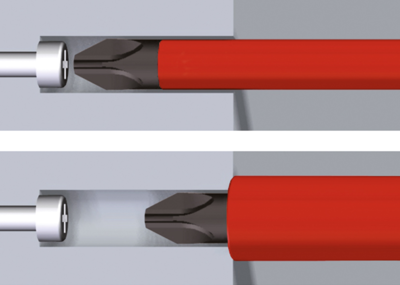

Tested tools are labeled with a special seal that provides information about the inspecting company and the certification date.

Did you know? Products that show serious deficiencies and safety risks during such a test procedure must also be labeled. They receive a special warning sticker. There is also an obligation to notify the responsible safety officer or the system operator.

VDE standards, the law or voluntary action?

Standards per se are not binding laws. The implementation of VDE standards is therefore voluntary. They only become legally binding when they are defined as mandatory by laws, ordinances or contractual partners. The fact that the regulations nevertheless play an essential role is due to the high status of standardization.

Legal protection by VDE regulations

These “recognized rules of technology” also provide legal protection for the technicians who adhere to these specifications. This is because the VDE standards are recognized safety standards. They are therefore considered to be the decisive criteria for assessing product conformity. Failure to comply with them can have legal consequences.

Safety relevance

Products that are VDE-compliant are considered tested and reliable in terms of electrotechnical safety requirements. This can increase confidence in these products among consumers and in the commercial sector. The importance of VDE standards underlines Germany’s role as a pioneer in global standards for safety and quality in electrical engineering and related industries.

VDE guidelines and their international context

Tools and workshop equipment with the VDE test seal are also convincing on an international level. Companies that want to market or use their products worldwide benefit from compliance with harmonized or internationally recognized standards. The rules are important resources for manufacturers, engineers and technicians worldwide. The standards enable them to use their tools and systems successfully and legally compliant in Germany as well as on international markets. The need to comply with different national standards is reduced. need to comply with different national standards is reduced. rmany’s role as a pioneer in global standards for safety and quality in electrical engineering and related industries.

The creators of DIN-VDE standards

The VDE standards are adopted by the DKE (German Commission for Electrical, Electronic & Information Technologies) within DIN (German Institute for Standardization) and VDE (Association for Electrical, Electronic & Information Technologies). As Germany’s central institution, the DKE is responsible for the development of standards and safety regulations in the field of electrical engineering. While the DIN is primarily dedicated to general, national standards, the VDE focuses specifically on the definition of electrotechnical specifications. This is why the regulations are also known as DIN-VDE standards.

Types and fields of application of VDE standards

The complete DIN-VDE regulations includes over 3,500 standards – and there is a reason for this. They significantly define the quality and safety standard of all steps and every piece of equipment in electrical installations, no matter how small. Whether in industry, trade or in public and private buildings.

VDE standards therefore exist for many large subject areas such as information and communication technology (from DIN-VDE 0800). However, they also deal with supposedly “small” work steps such as the correct stripping of electrical equipment (VDE 0100 series). The fact is that the safety of electrical installations is covered throughout with standards – from planning and implementation through to testing and maintenance.

The most important VDE standards in overview

The mass of directives results in series of standards in different sub-areas, which are identified by the first two digits of the four-digit numerical coding. We offer you an overview of the most important groups and individual standards:

- DE 0100 series: Installation of low-voltage systems – Basis for the installation of electrical systems. The series of standards contains general protective measures and requirements for electrical installations to ensure their functionality and user safety.

- VDE 0105-100: The standard “Operation of electrical installations” refers to the requirements for the proper operation and maintenance of electrical installations.

- VDE 0701-0702: These standards regulate the testing after repair of electrical equipment and the “periodic testing of electrical equipment”. They provide regulations for the safety testing of electrical devices after repair or during regular maintenance.

- VDE 0500 series: This subgroup describes how to ensure the electrical safety of machines and systems. It also regulates various converters such as transformers or storage devices (batteries, accumulators).

- VDE 0600 series: This group of standards includes nominal specifications for the installation material of electronic devices, such as standardized switches.

Local scope of the VDE standards

VDE standards primarily apply in Germany, as they are specifications of the Association of German Electricians. However, as many of these directives are harmonized with international standards or international standards (IEC standards) are directly adopted as VDE standards, their application can also be relevant beyond Germany. EU-wide, for example, some VDE standards can be used for conformity assessment as part of the “New Approach” principle. This means that VDE-tested products can be placed on the entire EU internal market more easily, provided they are labeled as harmonized.

When do VDE standards become applicable?

The validity of a VDE standard begins with its publication by the VDE itself. After publication, it can be used by manufacturers, testing institutes, authorities and various interest groups. New products or installations are generally expected to comply with the current VDE standards. However, there may be transitional periods during which the old and new standards apply in parallel to give manufacturers and service providers time to adapt.

Buy VDE-certified tools at Bürklin Elektronik

Did you know? When you browse through the range of tools and workshop equipment in the Bürklin Elektronik online shop, you have the option of selecting the filter attribute “VDE-/1000V-tested”. This preselection will lead you even faster to the standardized product you are looking for. Do you still have questions about standards and regulations? Use our digital contact form! Our competent customer service team will provide you with comprehensive advice.