Sustainable Manufacturing: Sustainability Approaches for the Manufacturing Industry

How can the manufacturing industry become more sustainable and what are the benefits? We highlight various sustainability approaches - from raw material management to circular economy to CSR reporting. We also show why sustainable manufacturing not only benefits the environment, but also the company itself. Read on to find out how you can make your production fit for the future.

Table of contents

- The advantages of sustainable manufacturing

- Sustainability through raw material management

- Sustainability through a circular economy

- Sustainability through digitalization

- CSR reports as a tool for greater transparency in environmental protection

- Towards more sustainable manufacturing with Bürklin Elektronik

There is potential for improvement in terms of sustainability along the entire value chain – starting with the selection of raw materials, through energy and heat recovery, to low-emission transport routes and ecologically sensible production sites. It is therefore obvious that in order to operate sustainably, a holistic view of the company’s processes is required. A strategic approach to these three cornerstones is essential:

- Raw materials management

- Circular economy (circular action)

- Digitalization

The advantages of sustainable manufacturing

Even if the switch to greater sustainability is often laborious and – at least for the time being – comes at a high cost: in the long term, a change in terms of environmental compatibility is well worth it. Particularly lucrative incentives:

- increased efficiency

- high cost savings

- greater safety through reduced risk

- brand positioning

Sustainability through raw material management

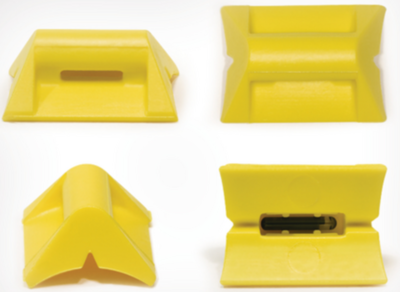

The choice of material points the way to more sustainable manufacturing. Ideally, the more ecological the starting material, the lower the impact of the products on nature and the environment. Compliance with sustainability standards, certifications, but also a sense of social responsibility play fundamental roles. If possible, recyclates should be the focus in terms of environmentally friendly procurement of raw materials.

However, recyclates are highly variable in quality and value. For example, grade purity in the collection of the used material makes a decisive difference. The resulting material quality also determines its subsequent use in production. Critical areas for the use of recyclates are still the food and safety industries. There is a risk of excessive wear or contamination. Strictly speaking, it is usually not possible to speak of recycling at all. This is because the recycled product is rarely used as a direct replacement for the original, but rather as an inferior variant.

Do we need a resource turnaround?

In relation to resource efficiency, the so-called resource turnaround, which is supposed to accompany the energy transition, comes up again and again. This is primarily about the way we deal with primary raw materials. The focus is on saving them in absolute terms and changing our usage behavior in the sense of a circular economy.

Sustainability through a circular economy

The motto is to move away from one-time use and constant new production, which generates huge amounts of waste. In the course of the circular economy, this is exactly what becomes possible: reuse through repair and recycling is the focus here. If the product life cycle is viewed holistically, the subsequent impact of product use on the environment can be taken into account as early as the design stage. Reusable or easily recyclable materials promote an economic cycle whereby products can be returned entirely to the manufacturing level at the end of their useful life. Closed-loop systems are designed to minimize waste and optimize resource consumption in the long term.

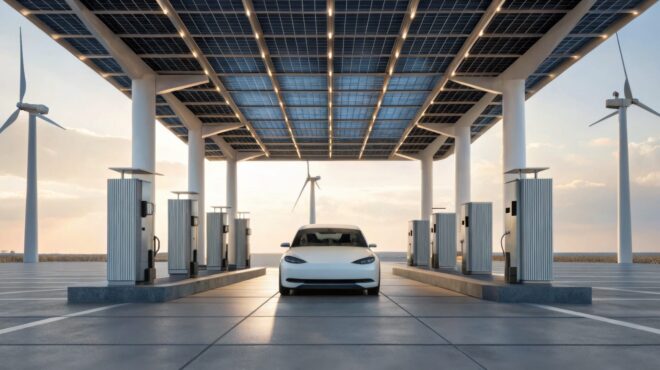

Another approach is to integrate renewable energies into circular economy systems. Solar systems on factory roofs can help to cover the company’s own electricity requirements and thus make production processes more sustainable. The self-generated energy flows directly into the manufacture of the end products as “clean” electricity from sustainable sources.

The need for new utilization concepts

Circular management must therefore be driven forward – but this also requires raw materials to be used differently. Alternative utilization models such as sharing and leasing instead of the classic sale are highly in demand. The resource remains the property of the manufacturer – and the manufacturer therefore has a greater responsibility. After all, if resources are limited, the producer must reclaim and recycle the material. He also wants to be able to offer his goods for as long as possible via leasing or sharing – increasing product quality and a longer service life are the consequences. The result: primary raw materials are used more efficiently.

Sustainability through digitalization

Digitalization offers enormous potential for greater sustainability in the manufacturing sector. The introduction of digital twins – digital copies of existing or planned manufacturing processes – drastically increases the opportunities for optimization. Consistent digitalization leads to greater transparency in the individual manufacturing stages and identifies weak points, errors and inefficiencies at an early stage. As a result, energy and materials are used more efficiently and CO2 emissions are reduced.

Insights through digital traceability

In addition, digitalization technologies can also be used to mark the material and information cycle. This allows companies to better monitor the entire production process and create synchronicity between the flow of materials and information. By improving the traceability of material flows, companies can also further reduce their ecological footprint and promote the circular economy.

CSR reports as a tool for greater transparency in environmental protection

Corporate sustainability reports (CSR reports) are used by companies to disclose their performance, efforts and goals with regard to environmental protection. Capital market-oriented companies with more than 500 employees and annual sales of more than 40 million euros have been required to prepare such a report since 2017. In the future, however, many more companies will be affected.

In terms of content, the CSR reports are subject to binding EU standards. The basic aim is to identify and fulfill responsibility for the environment, the workforce and society as a whole. In a detailed sustainability report, companies list, for example, their measures to reduce electricity and heat requirements, such as the installation of photovoltaic collectors or heat recovery. CSR reports also include steps taken and planned to improve procurement logistics and resource efficiency. In this way, companies can clearly and seriously demonstrate how they are actively contributing to the energy transition and reducing their own CO2 emissions.

Towards more sustainable manufacturing with Bürklin Elektronik

In the Bürklin Elektronik online store, you will find energy meters, monitoring relays and intelligent control systems, as well as various sensors, LED lighting solutions and much more.

In addition, Bürklin Elektronik has a team of experts to help you with any questions or problems you may have on the subject of sustainability. Tell us about your concern by e-mail to [email protected] – our employees will be happy to help you.

Interested in more exciting articles on topics such as smart buildings, e-mobility or solar technology and PV systems? Be sure to check out other articles!