Decentralised Control Unit with Multiple Installation Points

Today's industrial landscape is characterised by constant change and increasing demands. Flexible and efficient control of production processes is becoming more and more important. Decentralised operating units are essential components for this, for controlling and monitoring machines and systems directly on site. Together with RAFI, we take a closer look at decentralised solutions.

Flexible control units for optimised production processes

In modern industrial environments, efficient and flexible control of production processes is of crucial importance. Decentralised control units play a key role when it comes to controlling and monitoring machines and systems directly on site.

Particularly in large production facilities or networked systems, where a central control system is often no longer sufficient, decentralised solutions that can be operated quickly and intuitively are in demand. These systems must be seamlessly integrated into existing infrastructures and at the same time be adaptable and robust enough for different areas of application.

Whether in the automotive industry, in logistics or in mechanical engineering – flexible operating units are an advantage wherever production processes need to be monitored, controlled or adapted.

They enable personnel to act directly on the machine, to rectify faults or to make adjustments without having to travel to the central control system, which takes time. In addition, modern control solutions are increasingly being equipped with sensors and actuators to enable comprehensive data analysis and process optimisation. Efficiency, safety and user-friendliness are at the heart of this, to ensure optimal production.

Decentralised control units from RAFI

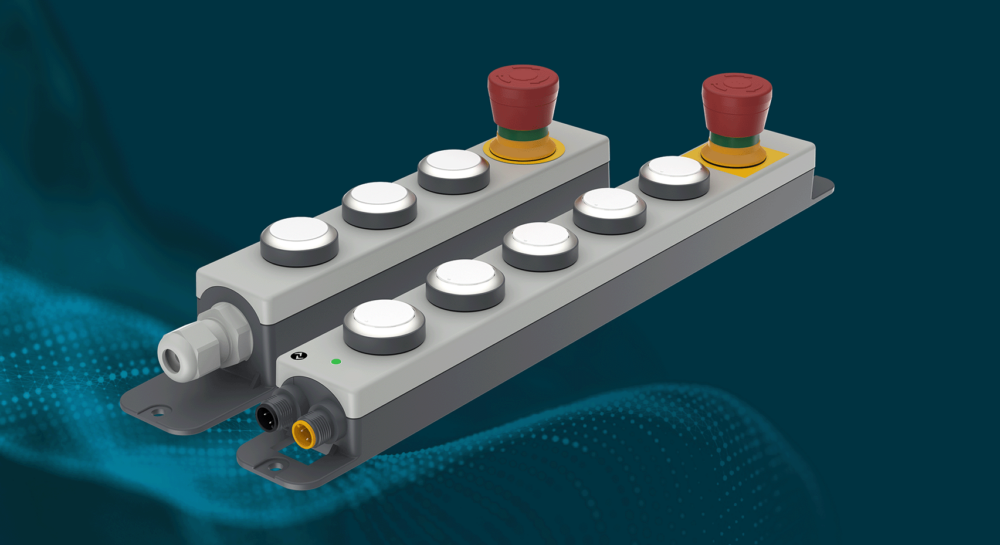

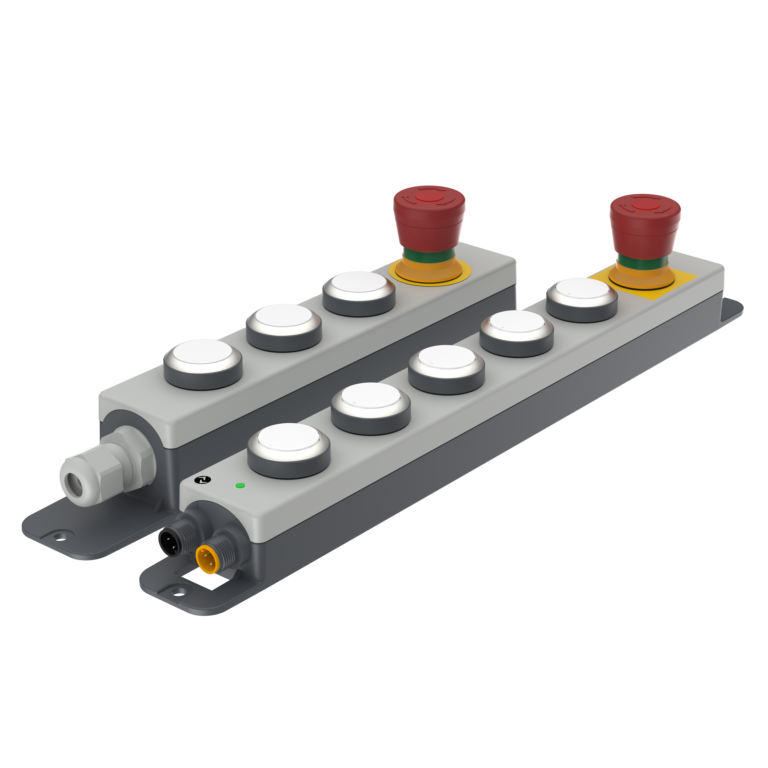

The new E-BOX XL offers versatile solutions for decentralised operating units in mechanical and plant engineering, robotics and automation, and intralogistics. With its slim housing design, simple screw mounting and up to six installation points, it is perfectly tailored to the requirements of modern production environments.

Both variants – MODULAR and IO-LINK – are characterised by a robust design (protection class IP65) and a wide operating range (-25 °C to +70 °C), making them ideal for demanding environments. The key strength of the E-BOX XL lies in its flexibility, coupled with quick and easy commissioning.

E-BOX XL Modular from RAFI

The MODULAR version of the E-BOX XL allows for complete customisation of the control elements. Each installation point can be flexibly equipped, enabling the user to tailor the control unit precisely to their requirements. The E-BOX XL MODULAR is compatible with the RAFIX 22 FS+ actuators and the RAFIX QC switch elements.

This opens up a wide range of configuration options for integrating actuators such as pushbuttons, selector switches, key switches, and emergency stop switches. Each element can be combined as desired, allowing the development of customised solutions for different applications.

Manual wiring also allows precise control of the installation process. This flexibility makes the E-BOX XL MODULAR the ideal choice for individual solutions.

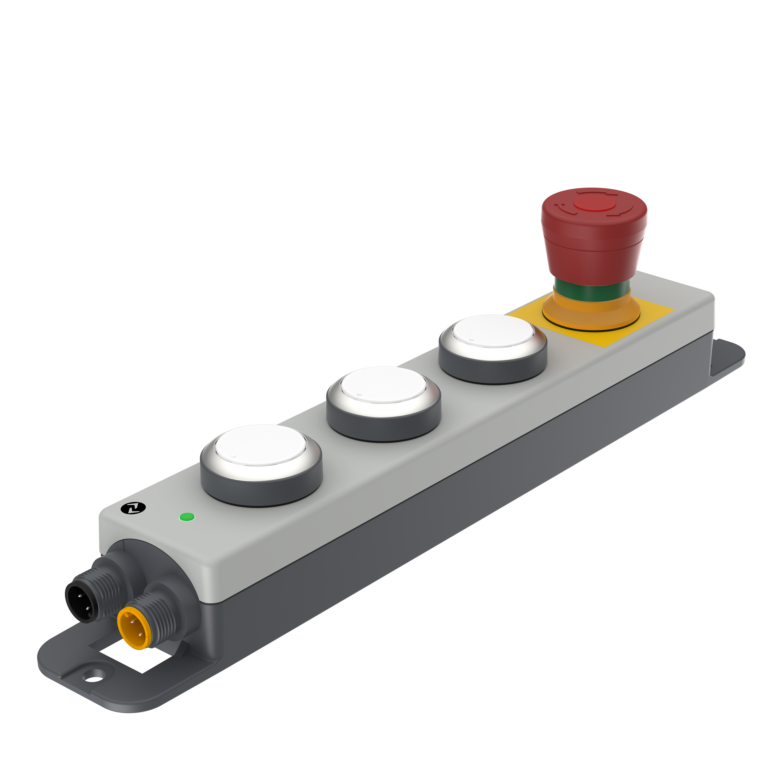

E-BOX XL IO-LINK from RAFI

The IO-LINK variant, on the other hand, offers pre-configured solutions and impresses with simple plug-and-play functionality. Here, the wiring effort is reduced to a minimum, since the pre-configured variants only have to be connected to the IO-LINK master port. This saves valuable time during installation and considerably simplifies integration into existing systems.

In addition, the IO-LINK variant enables advanced features such as RGB illumination parameterisation and monitoring of switching cycles. Up to six illuminated pushbuttons can be connected to just one IO-LINK port, which further minimises the cabling effort. Furthermore, the IO-LINK variant offers options for connecting additional sensors and actuators, making it a flexible and future-proof solution for a wide range of applications.