Maximum Safety and Efficiency: All Processes under Control with a Device Circuit Breaker System

Safe and efficient process sequences are crucial for industry to minimize downtimes and stoppages. With CAPAROC, Phoenix Contact has developed a customizable device circuit breaker system that ensures a direct and continuous supply and guarantees an uninterrupted supply even when modules are replaced. Learn more!

Table of contents

- Reducing complexity: Device circuit breaker as a key component

- Advantages of circuit breaker systems for developers and purchasers

- Advantages of circuit breaker systems during installation and commissioning

- Advantages for the operator: no system failures

- Safety first: Customized device circuit breaker systems at Bürklin Elektronik

Reducing complexity: Device circuit breaker as a key component

The reliability requirements for 24 V DC switchgear cabinet supply systems are continuously increasing. Therefore, more and more systems rely on high-quality power supplies, redundancy and USP modules in combination with electronic circuit breakers and remote monitoring mechanisms. However, the planning, combinatorics and procurement of suitable components as well as the design of such supply systems are becoming increasingly complex. Individual components such as circuit breakers can help reduce this complexity.

In general, the component “circuit breaker” is mainly associated with the protection of cables and wires against overload and short circuit, as described in DIN VDE 0100-430:2010-10: “Erection of low-voltage installations – Part 4-43: Protective measures – Protection against overcurrent”. However, circuit breakers can do much more than just these basic functions. An excellent example of this is the CAPAROC customizable electronic circuit breaker system from Phoenix Contact, which is capable of operating even more effectively and flexibly than conventional circuit breakers.

Advantages of circuit breaker systems for developers and purchasers

There are numerous advantages for developers and purchasers when using electrical components and assemblies. One of the biggest hurdles in their use is design-in by electrical development. Here, CAE-supported developers are expected to have a complete digital setup. CAPAROC begins this process at the component selection stage. The configurator on Phoenix Contact‘s website can be used to quickly and easily put together the right device circuit breaker system from components and supplementary services. Various modules are available for this purpose:

- Power supply modules with or without communication interface

- 1-channel device circuit breaker modules with four output terminals

- 2-channel device circuit breaker modules with two output terminals per channel

- 4-channel device circuit breaker modules with one output terminal per channel

- potential distribution modules

- modular busbars

Afterwards, further adjustments can be made, such as defining the individual rated tripping current per channel or personalized labeling of the modules and channels. Despite the large number of possible combinations, the configuration process always results in a unique and permanently valid article number and configuration ID. This greatly simplifies the subsequent ordering process for the entire device circuit-breaker system. In addition, the configuration can be retrieved at any time using the ID and adapted to current requirements. This also makes planning changes and conversions easier.

In addition, the configurator provides a wide range of system data sheets, labeling, 2D and 3D data, and Eplan data. This extension significantly enhances the so-called digital twin, as not only the individual components, but also the entire 24 V DC fuse protection system is displayed completely and comprehensively.

Individual part numbers and configuration IDs

When ordering individual components, the views resulting from the digital data sheet can help to ensure that the individual parts are assembled in the correct sequence. Purchasing can now integrate the unique part number and configuration ID directly into its ordering processes, eliminating the tedious search for accessory parts. The configuration of the safeguarding system is delivered in its completeness, exactly as required by the developer for the functionality of the application.

Thanks to the possibility of personalization, additional benefits open up for developers and purchasers, as only one master date is required for the entire configuration. As is generally known, the creation and updating of master data requires a considerable amount of time and incurs costs.

Advantages of circuit breaker systems during installation and commissioning

After new assemblies are developed, they are initially unknown to production personnel. This can result in considerable time spent during installation and commissioning. If the CAPAROC fuse system is not purchased as a finished module, it is easy and intuitive to assemble thanks to the tool-free plug-and-play plug-in technology. The colored controls and simple push-in direct plug-in technology also prevent errors when connecting the modules. If the safeguarding system has not already been preset, it can be adapted to the application via LED buttons or rotary switches on the modules or centrally via the communication interface.

It is important that all channels are clearly labeled to facilitate installation, initial commissioning, subsequent maintenance and possible troubleshooting. Ideally, the labeling has already been defined in the planning stage and integrated into the part number to minimize the labeling effort in production.

Advantages for the operator: no system failures

In a 24 V DC supply system, there are three challenges in using redundancy, USP and monitoring mechanisms. These are:

- Undervoltage: when the upstream power supply has a fault (such as phase failure) or is “decrepit”.

- Overvoltage: When the upstream power supply regulation is faulty (and there is a 32 V output voltage limit), resulting in a voltage spike.

- Current draw above 80 percent of the set nominal value: This can be caused by an increased load from connected motors or actuators, or by a creeping ground fault in the consumption path.

In addition to these three externally influenced process states, there are also two internal states that are detected by CAPAROC:

- Channel fault on at least one channel.

- Total current shutdown above 45 A: Modules are shut down in a prioritized manner to prevent system overload.

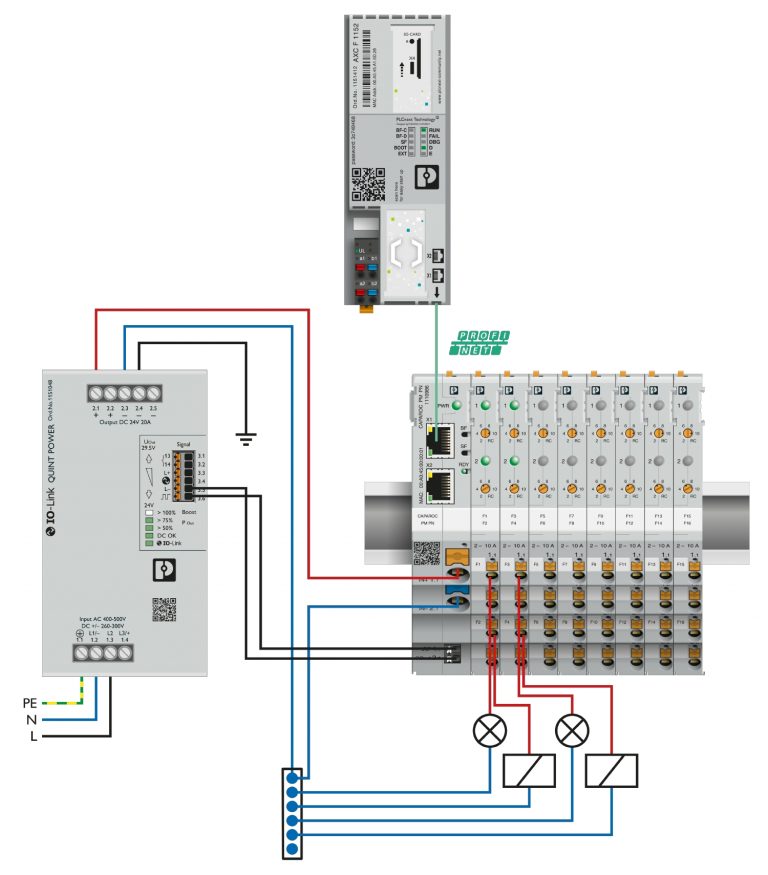

The operating states of the individual CAPAROC circuit breaker modules are collected and reported to a central control room or controller via the communication interface. Depending on the process status, precautionary measures are initiated and triggered channels can be reset via reset command. On site, the operating states are signaled directly at the channel by colored LEDs. If a CAPAROC circuit breaker module is defective, it can be replaced during operation without affecting the rest of the protection system.

CAPAROC’s circuit breaker system provides additional safety to the plant operator because it can be globally locked against two unwanted external influences. These are the rated current programming lockout, which locks out rated current programming on all circuit breaker modules, and the user interface lockout, which completely locks out operation of the circuit breaker modules via the pushbuttons and rated current rotary switches. Thanks to these protection mechanisms, CAPAROC contributes significantly to maximum plant availability.

Safety first: Customized device circuit breaker systems at Bürklin Elektronik

Until recently, it would have been impossible to imagine such a total package as that offered by Caparoc in a circuit breaker system. CAPAROC offers a wide range of benefits, including:

- Possibility of personalization

- Reduction of master data requirements

- Complete digital data package

- Tool-less mechanical assembly

- Fast installation and commissioning

- Easy maintenance and fast troubleshooting

- Comprehensive information on the status of the supply system

As a result, the complexity described above can be reduced considerably, leading to a significant increase in plant availability.