PCB connectors from Phoenix Contact: The Future of Interconnection Technology

With their innovative technology and performance range, the new PCB connectors from Phoenix Contact enable seamless integration of electronic components and contribute to the development of state-of-the-art devices and systems. We take a close look at the PCB connectors and shed light on their versatile application and groundbreaking technology.

What are PCB connectors?

PCB connectors are one of the most important components in the electronics industry. These small but crucial components enable the connection of PCBs and electrical devices. They serve as an interface between different electronic systems and thus contribute significantly to the function of devices such as smartphones, laptops or household appliances.

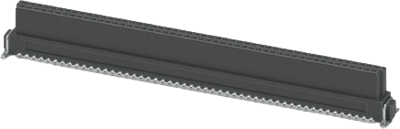

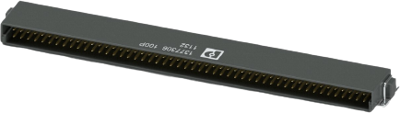

Choosing the right PCB connector is of great importance, as they must ensure reliable performance. A high-quality connector ensures a stable connection that will last even under adverse conditions. There are different types of connectors, including male and female connectors, spring contacts, and ribbon cable connectors.

Another important feature of PCB connectors is their adaptability to different applications. Depending on the requirements, they can be equipped with different contact materials and coatings to meet the specific needs.

Overall, PCB connectors are an indispensable part of the electronics industry. It is important to pay attention to quality and adaptability when selecting them to ensure smooth operation of electronic devices.

The Phoenix Contact FR 1.27 PCB connector: PCB connections for demanding applications

Since the 1990s, the 1.27 mm pitch has established itself as a quasi-standard in the field of PCB connectors. Thanks to proven contact geometries that use tulip and pin contacts, reliable signal transmission from one PCB to the next is guaranteed. Tape-on-reel packaging and SMD solder pads enable soldering that can be automated. The versatile board-to-board connectors are popular with customers from nearly all industries.

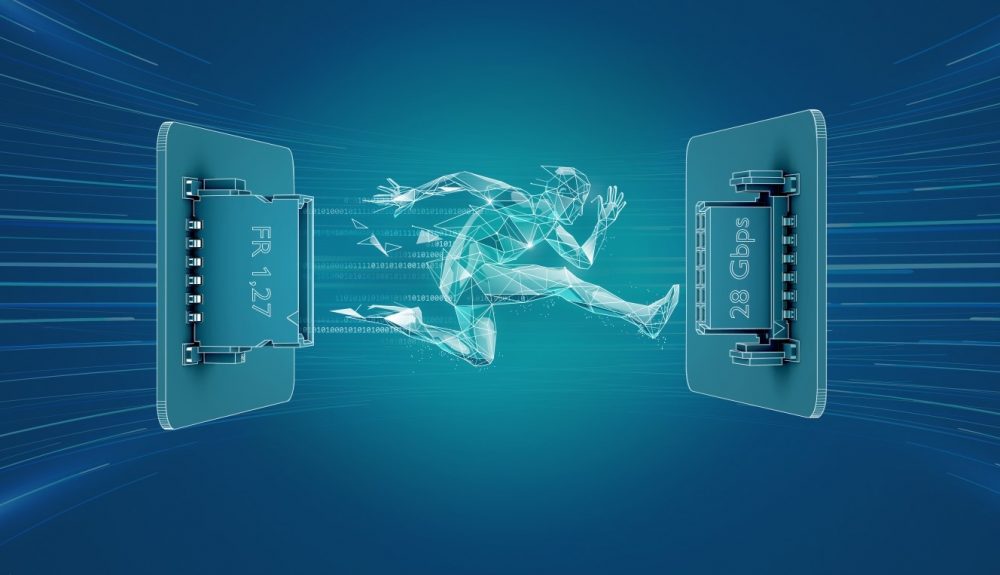

Phoenix Contact has given the FP 1.27 series, launched in 2018, and in particular the board-to-board connectors with a pitch of 1.27 mm, a facelift. The result: the new FR 1.27 product family, which was presented for the first time at the Embedded World trade fair in Nuremberg. In addition to new items such as an extended pole count spectrum and strain relief brackets for the IDC connectors, the FR 1,27 offers a variety of significantly improved item features that enrich the FINEPITCH product range.

Maximum performance: The advantages of the FR 1.27 PCB connectors

High-speed data transmission

Until now, transmission rates of a maximum of 4 Gbit/s were common for connectors of this type. But Phoenix Contact has its sights firmly set on enabling high-speed data transmission as well with the innovative FR 1.27 series. With these PCB connectors, it is indeed possible to achieve an impressive data rate of up to 28 Gbit/s.

Robustness

The wiping tolerance of 1.5 mm is an established feature of this specific connector type. In addition, it offers a contact reliability of 0.9 mm, which allows a total contact overlap of 2.4 mm when fully mated. This allows stacking heights from 8 to 13.8 mm in mezzanine configuration as well as various orthogonal and coplanar board connections without gaps.

Thanks to a positioning tolerance of 0.7 mm in all directions, precise placement is guaranteed. The angular offset during mating has also been improved and is now only 5° in all directions, enabling even easier handling.

Current carrying capacity

A clear increase in the products’ characteristics can also be seen in terms of current-carrying capacity. In the 6-pin version, one pin can carry around 3.7 A, while in the 100-pin version it is around 2.2 A per pin. This means that a total current rating of 220 A is possible for connecting boards with FR 1.27. For example, if 6 pins of the 100 are powered together and the adjacent pins in the layout are grounded, each of the 6 pins can carry a current of 3.7 A, for a total of about 22 A.

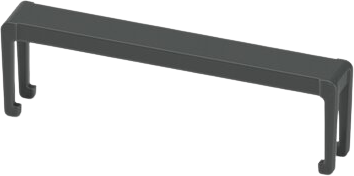

Ribbon boards

FR 1.27 not only provides rigid PCB connections, but also presents wire-to-board solutions that allow greater flexibility in PCB layout. A total of nine different pole numbers of IDC connectors are available both individually for custom assembly and pre-assembled as an assembly. In addition, the cable assemblies can easily be designed according to the specific needs of each customer using the online configurator.

Customized variants

Although the full energization of all contacts occurs rather rarely, the so-called hot-swapping of plugged-in PCBs and modules is used all the more frequently. The FR 1.27 series has been specially equipped for this purpose. In addition to the standard products, Phoenix Contact also offers customized male connectors with shortened contact pins, so-called “followers”. The new PCB connections also allow partial assembly and thus guarantee maximum flexibility for your requirements.

The features of the new FR 1.27 PCB connectors

- Pitch: 1.27 mm

- Number of poles: 6, 12, 16, 20, 26, 32, 40, 50, 68, 80, 100

- Stack heights: 8 – 13.8 mm (up to 20 mm from 2024)

- Data transfer rates up to 28 GBit/s

- Rated current: 2.3 A per contact

- Compatible with current market competitors

Innovations in printed circuit board connections

Phoenix Contact has developed a groundbreaking solution in the field of board-to-board connectors with the FR 1.27 series. The new connectors guarantee compatibility with common solutions on the market while offering improved article properties. This makes the board-to-board connectors future-proof and usable for many applications, even in the decades to come.