RAFI MICON 5 and RACON ST Tactile Switches – Robustness in Miniature Format

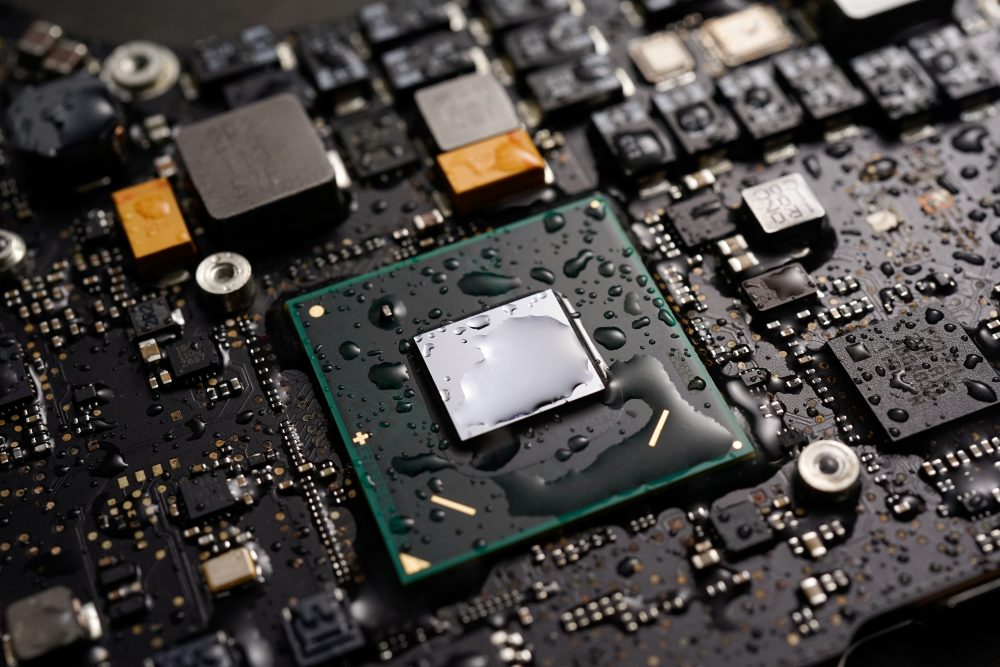

Sealing printed circuit boards is particularly difficult when electromechanical components such as short-travel key switches are installed. A price- and process-optimized nano sealing often fails due to the penetration of the solvent into the probe interior. The MICON 5 and RACON ST model series from RAFI revolutionize the short-travel switch market. They are particularly compact and suitable for all PCB sealing processes. We have taken a close look at the revolutionary tactile switches from RAFI.

MICON 5 from RAFI: Small pushbutton with a big effect

The MICON 5 product series from RAFI sets new standards in the area of switches. The short-travel switches in ultra-compact format are divided into three model series: MICON 5 S, MICON 5 SL and MICON 5 Safety. The pushbuttons of the MICON 5 series from RAFI meet the highest demands for durability and safety. Whether in the electronics industry, the automotive sector or medical technology, the switches can serve a wide range of applications.

The miniature units, measuring 5.1 x 6.4 x 3.85 mm, feature an optimized sealing system that gives them IP67 protection. This makes them ideal for the coating variants potting, selective and dip coating, and nanocoating with fluoropolymers. With a temperature resistance of 40 °C to +125 °C, they meet the current standards of the automotive industry. The high-quality gold contacts ensure lasting switching reliability.

The MICON 5 SL variant is specially designed for heavy-duty applications such as in joysticks and can withstand up to ten million actuation cycles. The SL variants are available both as SMT versions and with two different actuation forces to meet individual requirements.

The MICON 5 SAFETY series is characterized by two isolated normally closed and normally open contacts, which makes it unique in its size worldwide. The MICON 5 SAFETY complies with various standards and is suitable for safety-critical applications:

- IEC 61508 (basic standard of functional safety)

- IEC 62061 (safety of control systems)

- IEC 60601 (electrical medical devices)

- ISO 26262 (road vehicles)

- DIN EN 50128 (railroad applications)

- DIN EN ISO 13849 (Safety-related parts of control systems)

- DIN EN ISO 25119 (Control systems for agriculture/forestry)

MICON 5 S & MICON 5 SL: The features at a glance

- Compact dimensions

- Service life up to 10 million switching cycles (MICON 5 SL)

- Actuating forces from 1.5 N to 7 N

- Gold contacts for safe switching at low currents

- Unique tactile feedback

- Protection class IP67 (front and rear)

MICON 5 Safety: The features at a glance

- Unique worldwide: 1 NC contact + NO contact

- Operating temperature -40 °C to +125 °C

- Service life up to 1 million switching cycles

- Actuating forces from 2.9 N to 5.6 N

- Unique tactile feedback

- Protection class IP67 (front and rear)

RACON ST from RAFI: Small pushbutton, particularly robust

The customized RACON ST product series fits seamlessly into any operating system and offers the right short-travel key switch for every project. The new RACON ST series in the format of 12 mm x 12 mm or 8.4 mm x 8.4 mm with SMT or THT connection has been optimized by RAFI for all the PCB protection methods mentioned.

Thanks to its sealed design, the RACON ST can be used on PCBs that are optimally protected against environmental influences and contamination, whether by potting, painting or nanocoating. With its impressive temperature resistance from -40 °C to +125 °C, the RACON ST offers outstanding performance for automotive and other outdoor applications.

In addition to its impressive temperature resistance, the RACON ST features a dense, robust and gold-based contact system that ensures absolute switching reliability and resilience. With a guaranteed reliability of at least one million actuation cycles, the product series can ensure reliable operation.

RACON ST: Features at a glance

- Gold contacts

- IP67

- Operating temperature -40°C to +125°C

- Up to 10 million switching cycles

Excursus: What protection methods are available for printed circuit boards?

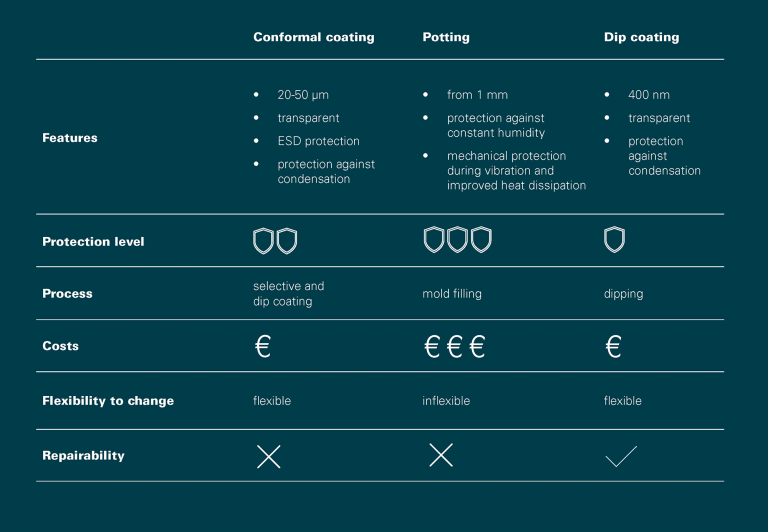

Safety through the potting process

In the manufacturing of electronic assemblies for applications that are susceptible to corrosion and dirt, the potting process is currently still preferred to ensure permanent protection against moisture and dust. In potting, the printed circuit board is either partially or completely filled with a medium such as epoxy resin, polyamide or polyurethane and admixed hardener. The viscous filling compound with a layer thickness of at least 1 mm not only prevents the penetration of dirt and moisture, but also improves heat dissipation.

In addition, the potting process prevents functional impairment due to mechanical effects. This makes the process particularly suitable for applications in construction and agricultural machinery. However, the costs are higher compared to protective coating and nanocoating, and it requires a time investment for potting and curing the medium.

Micrometer-fine protective coating

Another way of protecting printed circuit boards from external influences is the application of protective lacquer by means of dip coating, spray coating or selective machine coating. Depending on the medium and method used, coating thicknesses of 20 to over 100 μm can be achieved. The applied coating layer protects the electronics from dew, contamination and electrostatic discharge. The most common agents are acrylic and polyurethane coatings, but hybrid solutions such as silicone protective coatings are also used.

In the dip process, all exposed areas of the PCB are sealed – as long as there is sufficient clearance between the individual components. Before coating, components that could be damaged by the paint must be masked. This makes the process relatively material- and time-intensive.

In spray coating, lacquers with lower viscosity or diluted lacquers with solvents are generally used and sprayed onto the printed circuit board manually or automatically. This process is also used in selective coating, where only selected critical areas of the PCB are sealed to reduce material usage. A fast and homogeneous coating of the sections to be sealed without prior masking is achieved depending on the spraying precision and PCB design.

Nano Coating

Nano coating technology offers a particularly fast and economical method for liquid encapsulation of electronic assemblies. In this process, a fluoropolymer is usually used to immerse the assembly in a solvent bath such as hydrofluoroether. The dipping process ensures that all areas and components are coated with a homogeneous, extremely fine layer thickness of only 400 nm.

The nanocoating meets the requirements of the IEC 60068-2 group of standards for temperature and moisture resistance as well as protection against condensation and other climatic influences. The low material application, the short process time of just a few minutes, and the fact that masking and curing are not required make the nanosealing process extremely time- and cost-efficient.

In addition, the application of the process is environmentally friendly, harmless to health and free of unpleasant odors. Only PFOS-free, REACH- and ROHS-compliant substances are used. Nanocoating does not use conventional solvents or propellants, and thus differs from conventional protective coatings or potting processes.

It is repair-friendly, and components that can be desoldered can be easily replaced. Defective areas can be sealed with protective lacquer or the entire coating can be renewed. Due to these properties, the process is suitable across all industries for sealing electronic components that do not require increased vibration protection.

MICON 5 and RACON ST: New option for nano coating on short-travel key switches

Until now, there was no option for the use of nano coatings on printed circuit boards equipped with short-travel switches. The problem: During the dipping process, the solvent penetrates into the interior of the switches due to the capillary effect and settles on the switching contacts as a thick protective layer. This impairs the switching function. With the introduction of the MICON 5 and RACON ST product series, RAFI is the first manufacturer to offer a solution to this problem in the manufacturing of electronic assemblies.

With the tactile switches, which are suitable for all common coating processes, circuit boards with electromechanical actuators can now also be protected against corrosion, dust and dirt using a nano coating. This process-safe, time- and cost-efficient method increases cost-effectiveness, especially for standard assemblies manufactured in large batches.

The innovative micro short-stroke switches offer a new option for PCB coating for a wide range of industries from automotive manufacturing to maritime applications and power generation.