Electronics Industry in Transition: A Look into the Future

Sustainability is becoming increasingly important in the electronics industry. More and more manufacturers of electronic components and electronic parts are introducing sustainable, green product lines. But how sustainable is the electronics industry really? Bürklin Elektronik surveyed 400 workers in the electronics industry.

Sustainability approaches in electronics

Renewable energies such as solar energy and wind power are used across the board in the development and production of electronic components (81%). Only a small proportion (14%) do not use any renewable energies in the development and production process.

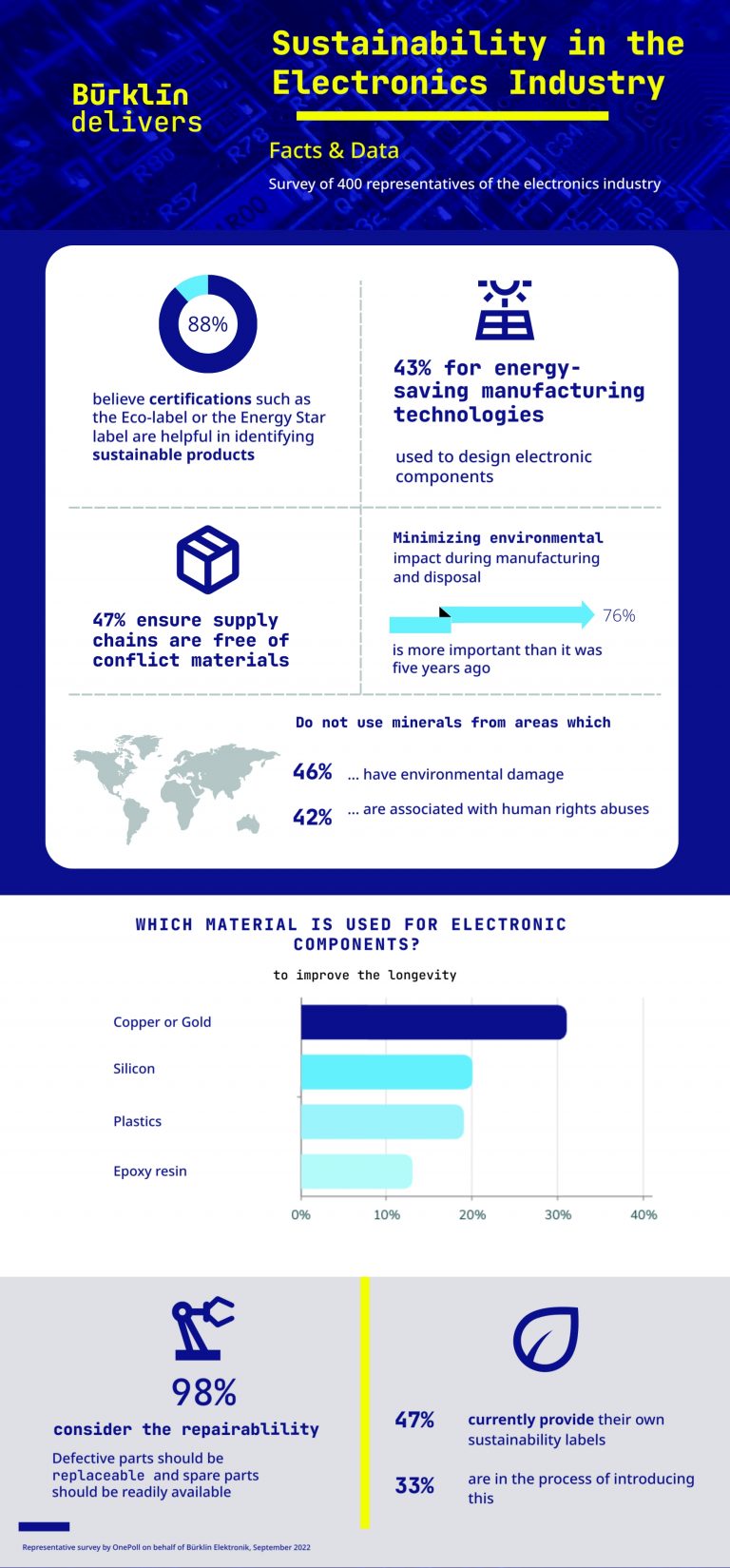

In addition to the use of energy-saving technologies such as solar energy (43%), the recycling of materials is also becoming more important (20%). Semiconductor materials such as SiC or GaN are also intended to help optimize energy consumption (20%).

Longevity of electronic components

The longevity of electronic components is not a new issue, but it remains an important one for manufacturers. To improve the longevity of products, metals such as copper and gold are used (31%), followed by silicone (20%) and plastics such as polyamides (20%).

Minimizing environmental impact more important than 5 years ago

Manufacturers already take reparability into account during the component design process (98%). For example, defective parts can be replaced more easily or instructions for repair or spare parts are offered. For 40%, repairability is particularly important, while only 1% do not consider it at all.

Electronics manufacturers consider minimizing the environmental impact and waste during production to be more important than in 2018 (76%), while only a fifth see no change here (18%).

Modular design is also a key element in the development of electronic components. More than nine in ten (94%) said that it is important to use modular designs to minimize electronic component waste. 46% say it is very important, while 1% say it is not important at all.

Sustainability labels on the rise

Certifications help to identify sustainable products. Almost one in nine consider official certifications such as the Ecolabel or Energy Star Label to be useful. In addition to independent certifications, in-house sustainability labels are also becoming increasingly important. Almost half (47%) already offer their own labels. A third are in the process of introducing such labels and 15% are planning to do so in the future. Sustainability labels are on the rise.

In addition, measures are being taken to create more transparency regarding the environmental impact of products. The availability of environmental impact documents for each product is at the very top of the list. More than half (54%) already provide information on the environmental impact, a third (34%) are in the process of providing this information and around a tenth (9%) are planning to introduce this.

Focus on conflict-free materials and supply chains

The fact that we use electronic devices that contain conflict materials is not an unknown problem. Relevant materials are often extracted under conditions that have serious consequences for workers and the environment.

We can see that manufacturers want to counteract this problem. Almost half (47%) state that their supply chains are free of conflict materials. 46% ensure that electronic components do not contain minerals extracted from areas with environmental damage. 42% ensure that no minerals are used that are extracted from areas where human rights violations occur.

An industry in transition

In general, sustainability approaches are becoming increasingly important in the electronics industry in the development and production of electronic components. In addition to the use of renewable energies, the longevity of products and their reparability are playing an increasingly important role. Certifications are designed to help identify sustainable products more effectively. Own sustainability labels are already being strongly promoted. Manufacturers are also paying attention to the environmental impact of their supply chain and making greater use of conflict-free materials and supply chains.

The survey was conducted on behalf of Bürklin Elektronik by the international survey institute OnePoll in September 2023. 400 workers in the electronics industry in Germany, France, Italy and the Netherlands were surveyed.