1021/G-A-1.5N-AU-2.0 | PTR

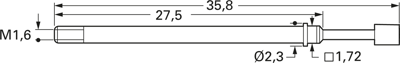

Threaded spring contact with probe, Concave, Ø 1.65 mm, travel 5.3 mm, pitch 2.54 mm, L 35.8 mm, 1021/G-A-1.5N-AU-2.0

High-current threaded spring force contacts, type PTR 10.

Design A: concave 90°. For connector pins, wire-wrap posts and straight / bent terminals. To be used on clean PCB because of the risk of contamination. W: pointed tip 30°, for PCB traces, through-plating, solder joints, and test pads. Design BS: practical flexible needle, point-of use reliable penetration of flux and coiling on unwashed PCBs or modules, or for contacting SMD. Design BST: sharp steel needle with endurance for reliable penetration of flux and dirt on uncleaned PCBs or modules and for SMD contacts. Design C: serrated, A universal head for straight or curved hookup wires, wire-wrap posts and connector pins. Design CS: serrated, with overlapping plastic insulation, presence test of component connections. The overlapping plastic insulation prevents electrical contact in places where the connection is missing. Design D: round head, for contacting PCB traces and contact surfaces. The round tip does not leave marks on the contact surface. Also used to contact socket contacts in connectors. Design E: convex, for clean vias or connector sockets. Design F: flat tip, used on tabs and clean convex contact surfaces to avoid damage to the surface. Design G: four-point crown, for hookup wires, solder joints and test pads without heavy contamination. Design H: pyramid, contact to plated through-holes without problems, also suitable for use on objects with flux residue. Design K: hexagonal, similar to H, but more aggressive and with higher contact reliability. Also used with rotary spring force contacts, cuts through oxide layers and dirt. Design M: crown, with overlapping center tip. The crown and central tip combination ensures reliable contact at almost any test point. The overlapping center tip fixes the probe tip. Design Q: 4-point crown, self-cleaning, for contacting on heavily soiled PCBs. The special cut of the tip discharges dirt to the outside.

Threaded test probes with probe tip series 1021/G.

Grid: 2.54 mm. Maximum travel: 5.3 mm. Working stroke: 4.0 mm. Spring force at working stroke (±20 %): 1.5 N. Spring prestress: 0.5 N. Current load: 5.0 to 8.0 A. Contact resistance: typ. 25 mohm. Barrel: gold-plated brass. Spring: gold-plated spring steel.

Technical attributes (type, tip shape, tip diameter, plunger material): 1021/G-A-1,5 N-Au-2,0, A, D 2.0 mm, steel.

| diameter | 1.65 mm | |

| Stroke | 5.3 mm | |

| Head shape | Concave | |

| Length | 35.8 mm | |

| Material | brass | |

| Rated current | 8 A | |

| Grid | 2.54 mm |

| Country of origin | TN |

| Customs tariff number | 85369095 |

| RoHS conform | Yes |

| Date of RoHS guidelines | 3/31/15 |

| SVHC free | Yes |